What is diamond grinding paste?

2024-03-27 10:15:54

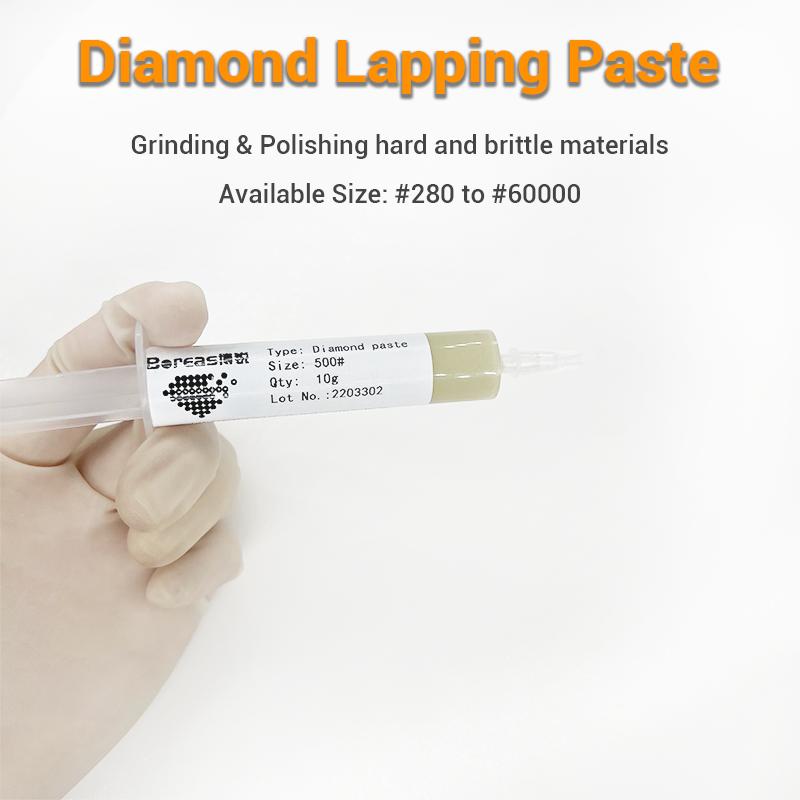

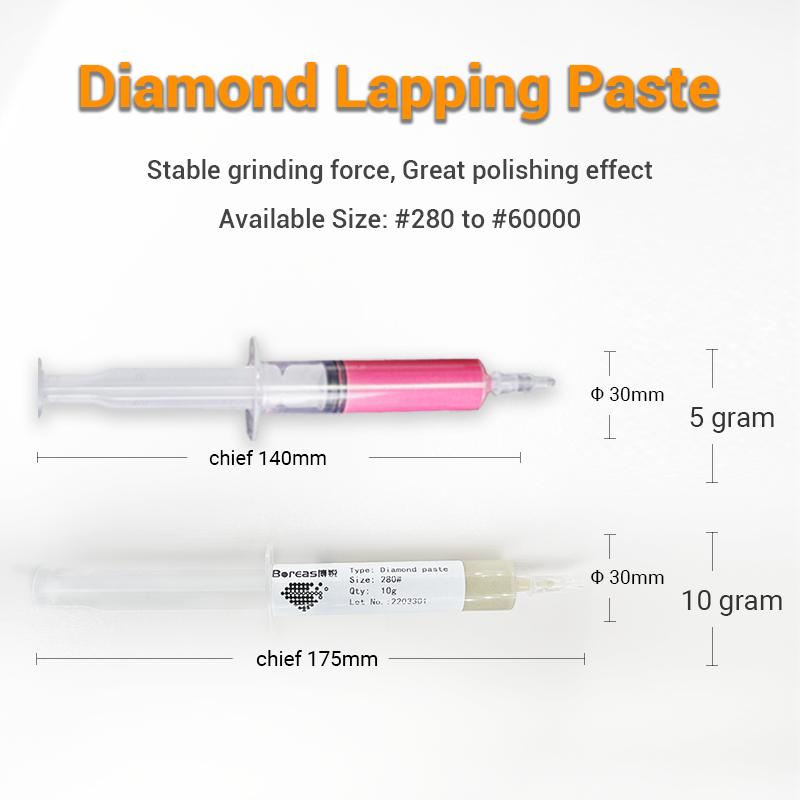

Synthetic diamond grinding paste is a kind of soft grinding paste made of finely selected high-quality diamond powder abrasives and paste binders, colorants, preservatives, flavors, etc. It is suitable for the grinding and polishing of measuring tools, blade optical instruments and other high-brightness workpieces of high-hardness materials such as glass, ceramics, gems and cemented carbides. It is also suitable for the special-shaped workpiece made of the above materials which is difficult to be processed by grinding wheel tools.

What is diamond grinding paste ?

Diamond Grinding Paste, also known as Diamond Grinding Paste, Diamond Grinding Paste

1、Diamond grinding paste categories and uses :

Diamond grinding paste can be divided into oil soluble diamond grinding paste, water soluble diamond grinding paste and water soluble dual-purpose diamond grinding paste ;

Oil solubility is mainly used for load mechanical grinding, polishing cemented carbide, alloy rigid, high-carbon steel and other high-hardness materials.

Water solubility is mainly used for fine research of metallographic and lithofacies samples.

2、Product characteristics :

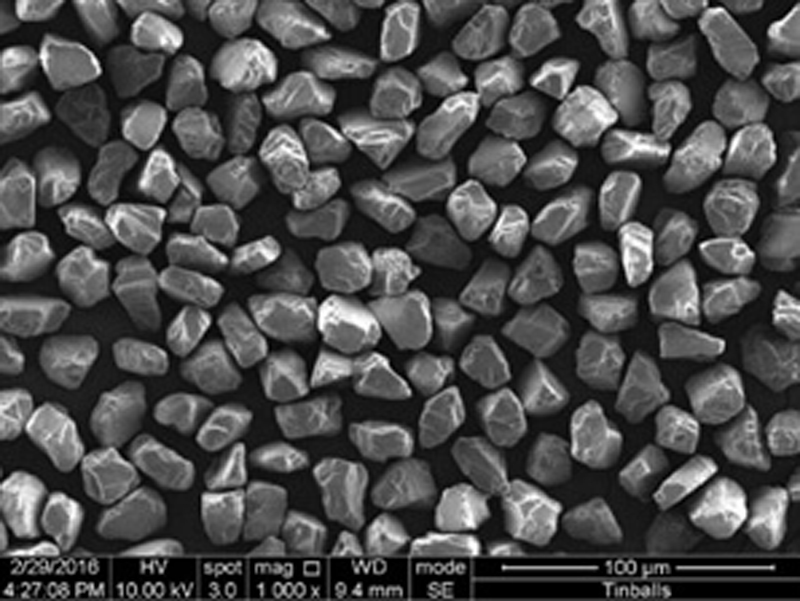

Diamond grinding paste is finely prepared with diamond powder and other raw materials. It is an ideal grinding paste for grinding and polishing, and has good lubrication and cooling performance. Diamond particles have high hardness and uniform particle size.

3、Application scope :

This product is suitable for glass, ceramics, cemented carbide, natural diamond, gem and other high hardness materials made of measuring tools, cutting tools, optical instruments and other high gloss workpiece processing.

4、Selection of diamond grinding paste :

The selection of diamond grinding paste is mainly determined by the requirements of workpiece smoothness, processing efficiency and original workpiece smoothness. If the processing efficiency is high, the coarse grain number can be selected ; if the quantity is small and the requirement is high, the fine grain size can be selected. Therefore, the coarse and fine research are generally selected according to the requirement of workpiece cleanliness.

5、Attentions in the use of diamond grinding paste :

According to the material and processing requirements of the workpiece, select the appropriate grinding device and grinding paste. Commonly used grinding machine is glass, cast iron, steel, aluminum, organic glass and other materials made of blocks and plates, diluent water soluble grinding paste or glycerin ; kerosene for oil-soluble grinding paste.

1. Diamond grinding is a kind of precision machining. The environment and tools are required to be clean and clean in the processing. The tools used are required to be specific for each particle size and cannot be mixed.

2. Workpieces must be carefully cleaned before switching to abrasives of different sizes during processing so as not to mix coarse particles of the previous process into fine-grained abrasives to scratch the workpiece.

3. When used, a small amount of grinding paste is squeezed into the container or directly squeezed into the grinding device, and diluted with water, glycerol or kerosene. The general proportion of water paste is 1 : 1, which can also be adjusted according to the field use. The finest particle only needs to add a small amount of water, and glycerol is added appropriately with the increase of particle size.

4. After grinding, the workpiece should be cleaned with gasoline, kerosene or water.

6、Matters needing attention in transportation and storage of diamond grinding paste :

1. Transportation and storage shall not be squeezed.

2.Storage temperature should be below 20oC.

3. Store in a sanitary, cool, dry place.