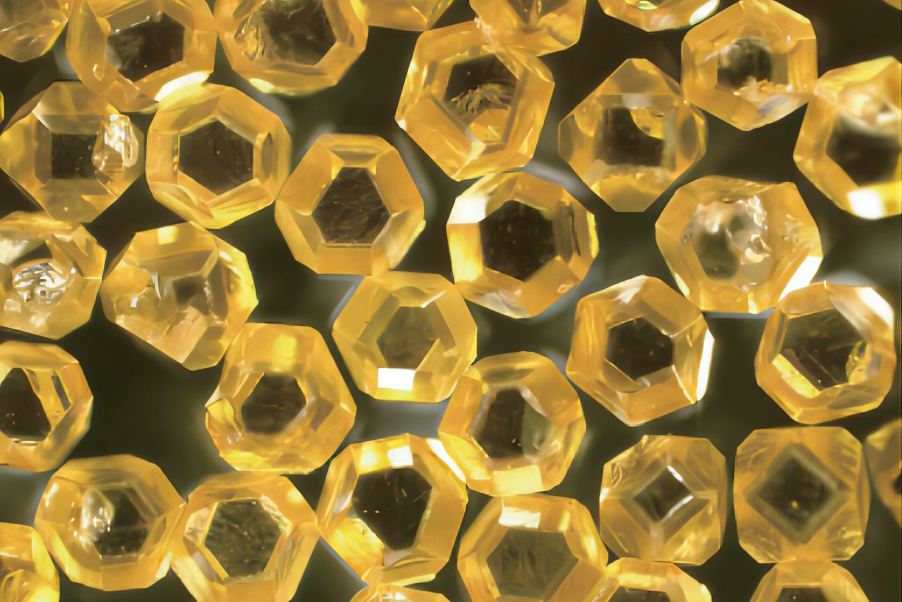

Cluster Diamond BRM-S

Cluster Diamond Description

|

Sapphire thin slices conventional processing |

New processing technology for sapphire thin slices |

Zirconia ceramic grinding and processing technology |

|||

Process flow |

Growing crystals—cutting bars—slicing— double-sided grinding—single-sided grinding—CMP fine polishing—cleaning |

Growing crystals—cutting bars—slicing—double-sided grinding—CMP fine polishing—cleaning |

Dry pressing/injection molding— Degreasing sintering—CNC carving— Grinding—Rough polishing—CMP fine polishing—Cleaning |

||

|

Polishing process/ consumables |

Double side polishing |

Single side polishing |

Double side polishing |

Single side polishing |

Surface polishing |

|

Cast iron plate + boron carbide grinding fluid |

Copper disc + diamond grinding fluid |

Resin polishing pad + polycrystalline diamond polishing fluid |

Resin polishing pad + polycrystalline diamond polishing fluid |

Profiled copperhead + polycrystalline diamond grinding fluid |

|

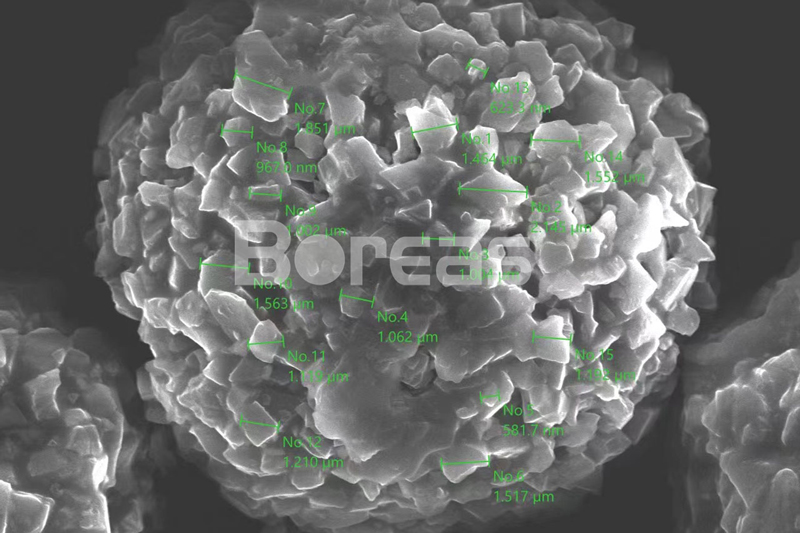

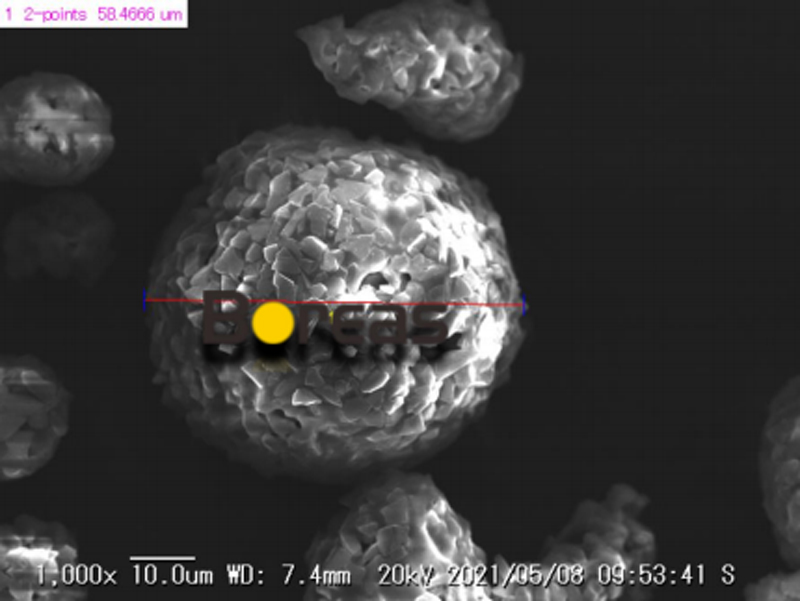

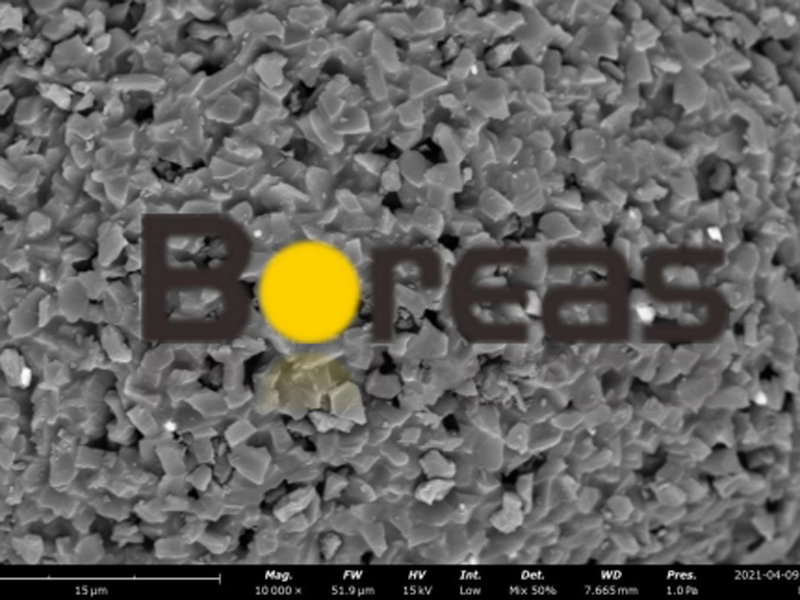

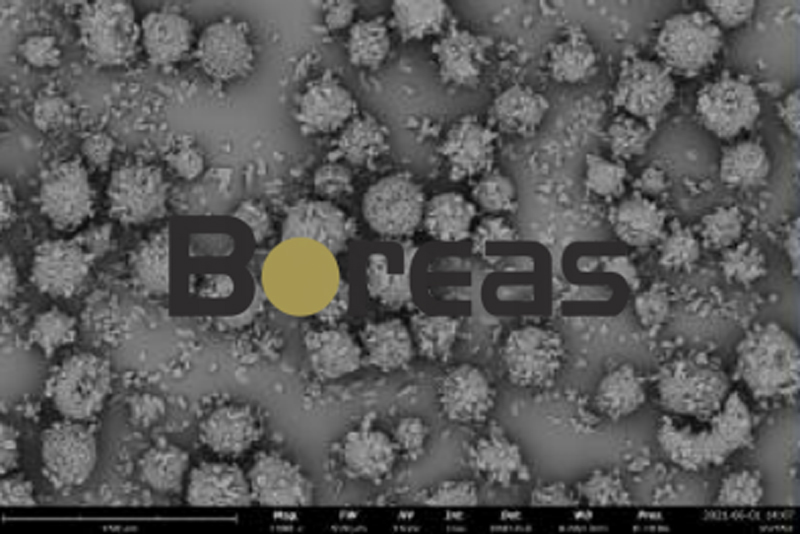

SEM of Cluster Diamond Powder

The physical and chemical properties of cluster diamond polishing liquid / pad

Brand |

Grain Size |

D50 |

Content |

PH Value |

Viscosity |

BRM0309 |

3.0μm |

30μm |

1% |

7.5 |

35mPa.S |

BRM0159 |

1.5μm |

35μm |

1% |

7.5 |

35mPa.S |

Comparing 3μm cluster diamond with others

-

BRM0159 Cluster Diamond

-

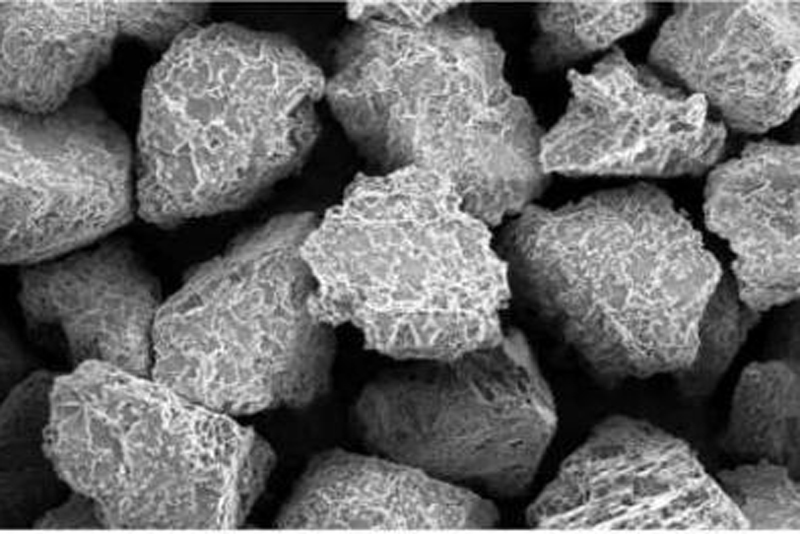

General Polycrystalline Diamond

-

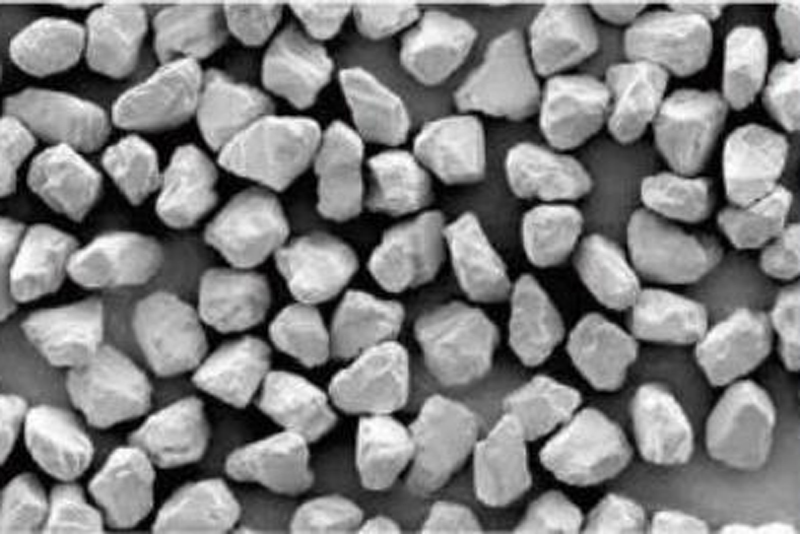

General Monocrystalline Diamond

![[BRM-A] / Blocky Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

![[BRM-B] Sharpened Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

![[BRM-GC] High Purity Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

![[BRM-GQ] High Strength Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] Micron Diamond Powder for Diamond Wire](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] Micron Diamond Powder for PCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] Reshaped Mesh Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] Crushed Mesh Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] Green Crushed Mesh Diamond](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)