0102030405

BRM-PD-Series

BRM-PD-Series

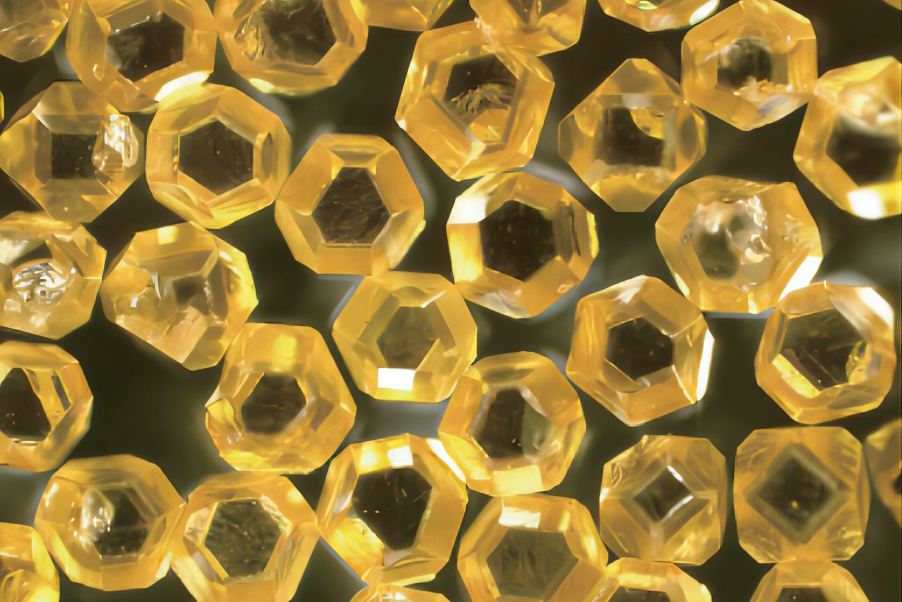

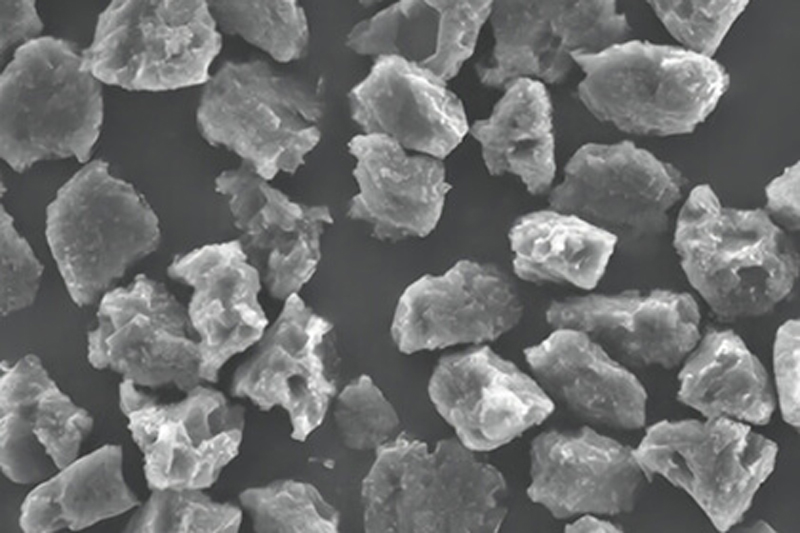

Characteristics of polycrystalline Diamond Powder:

( 1 ) The crystals are arranged in disorder, so the hardness is uniform and non-directional;

( 2 ) having high strength, especially impact strength and wear resistance;

( 3 ) Can be made into specific shapes;

( 4 ) The performance of a product can be designed or predicted to give it the necessary features to suit its specific uses;

Application

1. Surface polishing of various ceramics;

2. Applications in the field of high-end semiconductor materials;

3. Used as encapsulation material and magnetic recording system for IT products;

4. Lapping and polishing of semiconductor wafers such as SiC and sapphire wafers;

5. Used as a lubricant or oil additive, it can improve the operational performance of industrial machinery and vehicles, reduce faults and extend service life.

Nanocrystalline diamond can replace single crystal diamond in petroleum drilling, precision wire drawing and optical device processing.

Specification |

D10(μm) |

D50(μm) |

D90(μm) |

BRM-PD 0-1 |

≥0.05 |

0.40-0.60 |

≤1.00 |

BRM-PD 0-2 |

≥0.05 |

0.90-1.10 |

≤2.00 |

BRM-PD 1-3 |

≥1.00 |

1.90-2.10 |

≤3.00 |

BRM-PD 2-4 |

≥2.00 |

2.90-3.10 |

≤4.00 |

BRM-PD 2-5 |

≥2.00 |

3.40-3.60 |

≤5.00 |

BRM-PD 3-6 |

≥3.00 |

4.40-4.60 |

≤6.00 |

BRM-PD 4-8 |

≥4.00 |

5.90-6.10 |

≤8.00 |

BRM-PD 5-10 |

≥5.00 |

7.40-7.60 |

≤10.00 |

BRM-PD 6-12 |

≥6.00 |

8.90-9.10 |

≤12.00 |

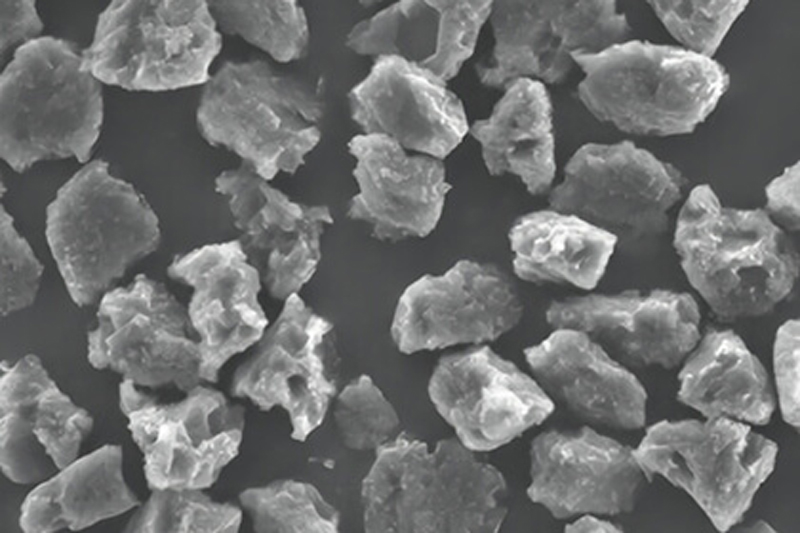

![[BRM-A] / Blocky Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

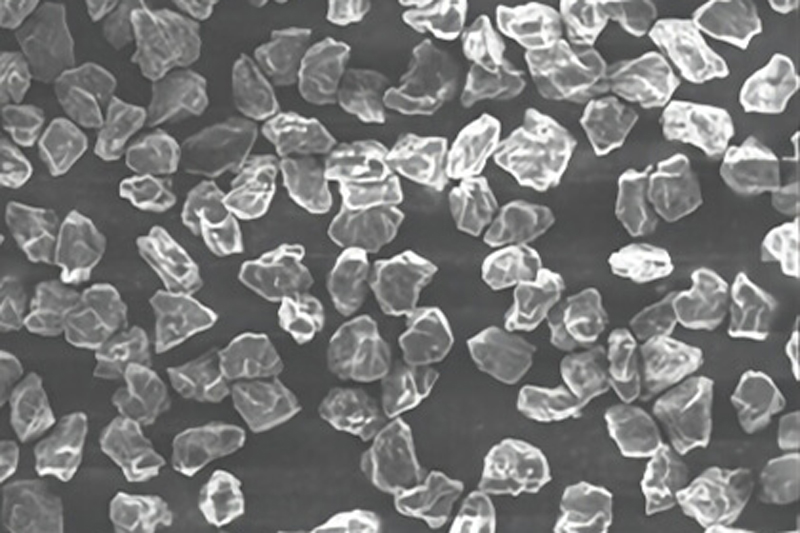

![[BRM-B] Sharpened Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

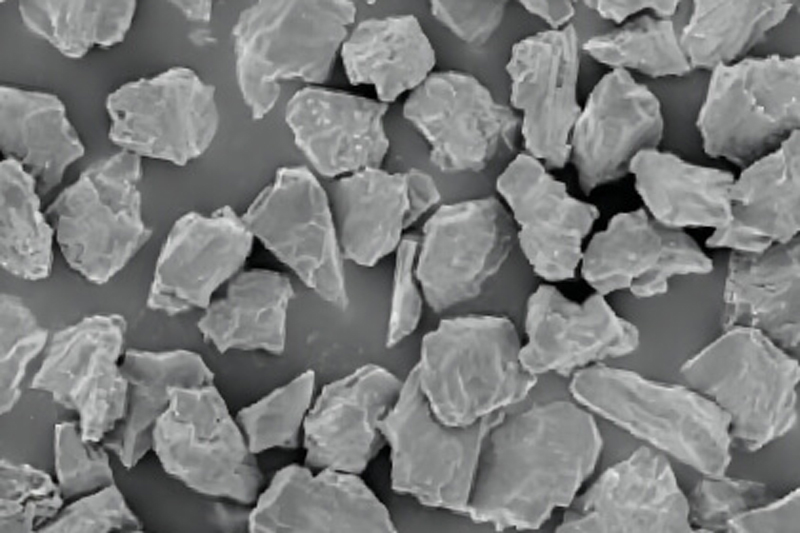

![[BRM-GC] High Purity Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

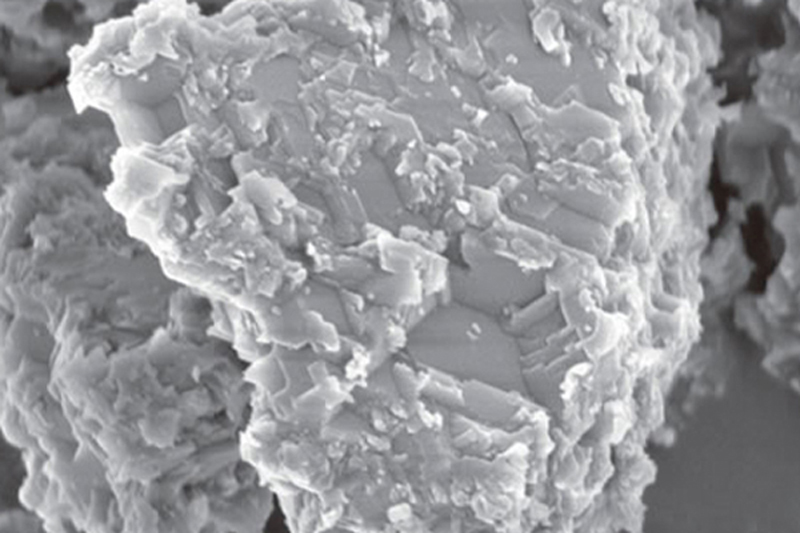

![[BRM-GQ] High Strength Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] Micron Diamond Powder for Diamond Wire](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] Micron Diamond Powder for PCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] Reshaped Mesh Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] Crushed Mesh Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] Green Crushed Mesh Diamond](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)