0102030405

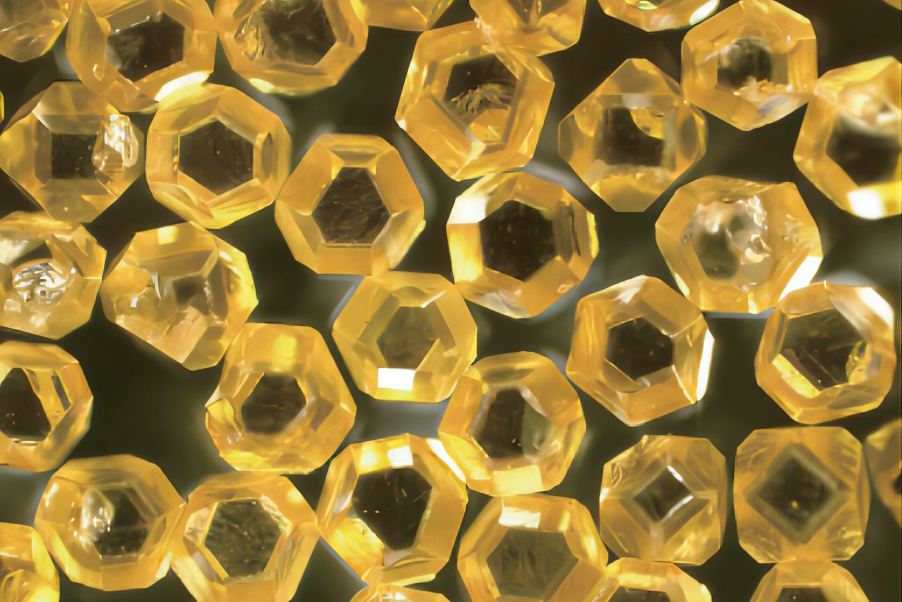

I-Polycrystalline Diamond

Izici zokusebenza ze-PCD

(1) Ukuqina okuphezulu nokumelana nokugqoka

I-PCD inobulukhuni obuphezulu, amandla acindezelayo aphezulu, i-thermal conductivity enhle kanye nokumelana nokugqokwa, ingaba ku-high-speed cutting ukuze ithole ukunemba okuphezulu kwemishini nokusebenza kahle kwemishini. izici ezinjalo zamathuluzi e-PCD zinqunywa isimo sekristalu yedayimane, isakhiwo sinamandla aqinile okubopha kanye nokuqondisa, ukuze idayimane ibe nobulukhuni obuphezulu kakhulu.

(2)Ukunemba okuphezulu kwemishini

Amathuluzi e-PCD ane-coefficient ephansi yokwanda okushisayo kanye ne-modulus ephezulu yokunwebeka, ngakho-ke amathuluzi akulula ukukhubazeka ngesikhathi sokusika, futhi ngesikhathi esifanayo, amandla okusika kanye nezinga lokushisa lokusika lingancishiswa ukuze kuthuthukiswe ukuqina kwethuluzi nokusika. isilinganiso, ukuze uthole indawo enhle yomshini.

(3) High conductivity ezishisayo

I-PCD conductivity eshisayo iphezulu kakhulu, ingcono kunesiliva, ithusi, futhi iphakeme kakhulu kune-carbide ejwayelekile, ngakho-ke kulula ukukhipha ukushisa enqubweni yokusika, futhi izinga lokushisa lokusika liphansi.

incazelo yomkhiqizo

(1) I-PCD kuzinhlelo zokusebenza zezimoto kanye ne-aerospace

Amathuluzi e-PCD emkhakheni wezimoto asetshenziswa kakhulu ukucubungula isiketi se-piston yenjini, imbobo yephini, i-cylinder block, i-gearbox nokunye. Ngenxa yokuqukethwe okuphezulu kwe-silicon yalezi zingxenye (ngaphezu kwe-10%), impilo yesevisi yezidingo zethuluzi, nokuqina kwethuluzi le-PCD izikhathi ezingu-1-50 ithuluzi le-carbide, lingaqinisekisa ukuzinza kobukhulu bezingxenye, futhi thuthukisa kakhulu isivinini sokusika, ukusebenza kahle kwemishini kanye nekhwalithi yendawo yokusebenza.

Emkhakheni we-aerospace, ukusetshenziswa kwamathuluzi e-PCD acubungula i-aluminium alloy (AlSi2) ikhanda lesilinda, izinga lokusika liphakeme, nempilo yamathuluzi kune-carbide enosimende ukuthuthukisa izikhathi ezingaba ngu-20, izinga eliphezulu le-workpiece nalo lithuthukisiwe kakhulu.

(2) I-PCD embonini yokucubungula izinkuni izicelo

Ukucubungula izinkuni nakho kuyindawo ebalulekile yezinhlelo zokusebenza zamathuluzi e-PCD. Ngokuthuthuka okusheshayo kwamaphaneli okwenziwa (i-medium density fiberboard, i-particleboard kanye ne-laminate flooring, njll.), kusheshisa isidingo samathuluzi okusika aqine kakhulu, ukuze amathuluzi e-PCD kancane kancane athathe indawo yamathuluzi okhuni endabuko emakethe.

Ungqimba olungaphandle lwe-Al2O3 lwe-laminate flooring lulimaza kakhulu ithuluzi le-carbide, futhi ukusetshenziswa kwamathuluzi e-PCD kungaxazulula le nkinga ngempumelelo. Ngakho-ke, i-PCD emakethe eyinhloko yemboni yezokhuni iqiniswa i-flooring eyinhlanganisela kanye nokuqina okuphezulu kwe-fiberboard processing.

(3) I-PCD kuhlelo lokusebenza lwemboni yokucubungula ngogesi

Imboni ye-elekthronikhi ekukhiqizeni amabhodi esekethe aphrintiwe kagesi ngokufunwa kakhulu, ithuluzi elijwayelekile elisetshenziswayo lizoba ne-burr, elithinta ukufakwa nokubeka izingxenye zikagesi, futhi lonke ibhodi lesifunda eliphrintiwe alihle; amathuluzi okusika i-carbide ekucubunguleni, impilo emfushane, isivinini sokucubungula esinensayo, ukusebenza kahle okuphansi, ukunemba komshini ompofu. Ukusetshenziswa kwamathuluzi e-PCD, ukusebenza kahle okuphezulu kokucubungula, izindleko eziphansi zokucubungula, ezisetshenziswa kabanzi.

(4) I-PCD ekusetshenzisweni kwemboni yokusika nokucubungula ingilazi

Isondo lokusika elenziwe nge-PCD lisetshenziselwa ikakhulukazi ukunemba okuphezulu, ukusika kwekhwalithi ephezulu kwezikrini ze-LCD zemikhiqizo kagesi, futhi ngasikhathi sinye lingasika ingilazi yokwakha kanye nemoto. Isondo le-mandrel ne-cutter lenziwe ngezinto ze-PCD, ezinezinzuzo zokunemba okuphezulu kokucubungula, ukumelana nokugqoka, ukungaguquguquki okuhle, nempilo yesevisi ephezulu ngesikhathi esifanayo, okwenza kube indawo ekahle yemimese yengilazi evamile namasondo okusika ingilazi ye-carbide.

(5) I-PCD embonini yezinhlelo zokusebenza ezihlanganisiwe

Isebenzisa amathuluzi e-PCD ukucubungula izinhlanganisela eziqinisiwe ze-glass fibre, impilo yayo yamathuluzi iphindwe izikhathi ezingu-60 kunamathuluzi e-carbide enosimende, izindleko zokucubungula ucezu olulodwa luyi-1/20 yamathuluzi e-carbide ayi-cemented, futhi ukunemba kokucubungula kuphakeme kunaleyo ye-carbide enosimende.

I-PCD

-

LTM2200

Usayizi wokusanhlamvu

Ukugqoka ukumelana

I-Electric Conductivity

Ukugaya

1mm

IIIIII

IIIIIIIII

IIIIIIIII

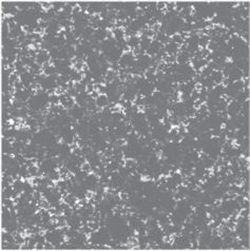

Izici:1. 1um isilinganiso sikasayizi wokusanhlamvu.2. I-LTM2200'S ultra-fine grain structure ifaneleka izinhlelo zokusebenza lapho kudingeka khona ukuqedwa kwesibuko ngenxa yobukhali baso obudlulele.Izicelo: Ilungele ukugaya nokusika ama-aluminiyamu ama-silicon alloys lapho kudingeka ukumelana ne-chip ngokwedlulele, nasekukhiqizeni i-titanium nezinhlanganisela.

-

LTM004

Usayizi wokusanhlamvu

Ukugqoka ukumelana

I-Electric Conductivity

Ukugaya

4mm

IIIIIIII

IIIIIII

IIIIIII

Izici;1. 4um usayizi wokusanhlamvu omaphakathi.2. Isakhiwo sokusanhlamvu esihle se-LTM004'S 4-micron sinikeza isengezo ekuletheni ibhalansi enkulu phakathi kokusebenza kwamathuluzi nokumelana nemihuzuko nama-chips.Izicelo: Ilungele ukusika ama-alloys e-aluminium lapho kudingeka khona ukuqedwa okuphezulu okuhambisana nokungagugi okuphezulu.

-

I-LTM10

Usayizi wokusanhlamvu

Ukugqoka ukumelana

I-Electric Conductivity

Ukugaya

10μm

IIIIIIII

IIIIIII

IIIIIIII

Izici:1. 10μm isilinganiso sikasayizi wokusanhlamvu.2. I-LTM10 iyizinga le-PCD elinamandla elilungele izinhlelo zokusebenza eziningi lapho kudingeka khona ukulingana okuhle kokuqina nokumelana nokugqoka.Izicelo: Ibanga elifanele lapho ukugoba nokuqeda kwenziwa ngethuluzi elilodwa. Kunconywe kakhulu kuma-alloys e-aluminium okuqukethwe okuphansi kuya kokumaphakathi.

-

I-LTM90

Usayizi wokusanhlamvu

Ukugqoka ukumelana

I-Electric Conductivity

Ukugaya

2-30μm

IIIIIIIII

IIIIII

IIIIII

Izici;1. I-PCD enamamodeli amaningi enenhlanganisela yamasayizi okusanhlamvu angu-2μm kuya ku-30μm.2. Yenziwe ngezingxube eziyingqayizivele kanye nezinga lokushisa eliphakeme elikhethekile kanye nobuchwepheshe bokuhlanganiswa komfutho ophezulu.3. Umkhiqizo unokumelana nokugqoka okuphezulu kakhulu nokumelana nokushisa.Izicelo: Iphumelele ekwenzeni ama-alloys e-silicon ephezulu ye-aluminium, izinhlanganisela ze-metal matrix, ama-tungsten carbides.

Uchungechunge lomkhiqizo olujwayelekile lwe-PCD

I-PCD Composite Sheet Product Series enoqweqwe lwe-Cemented Carbide | ||||||||||

Uhlobo | Idayimane (mm) Ukuqina Kwesendlalelo | Ubukhulu obuphelele (mm) | ||||||||

0.5 | 0.6 | 0.8 | 1.0 | 1.6 | 2.0 | 3.2 | 5.0 | 8.0 | ||

LTM2200 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM2200 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM004 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM004 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

I-LTM10 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

I-LTM10 | 0.5 |

|

| √ | √ | √ | √ | √ | √ |

|

I-LTM90 | 0.5 |

|

| √ | √ | √ | √ | √ | √ | √ |

Qaphela:

1. Ishidi eliyinhlanganisela elinogqinsi oluphelele elingu-0.5,0.6, no-0.8 alinikezi lonke ishidi, kodwa linganikeza ukusika okusanhlamvu kwe-kinfe noma ishidi elingu-1/4;

2. Ishidi eliyinhlanganisela elinogqinsi oluphelele luka-1.0, 1.2 no-1.4 alinikezi lonke ishidi, kodwa linganikeza ukusika okusanhlamvu kwe-kinfe noma ishidi elingu-1/2.

Imikhiqizo enogqinsi oluphelele luka-5.0 no-8.0 yimikhiqizo eyenziwe ngokwezifiso.

Abanye osayizi nezitayela kungenziwa ngokwezifiso ngokusho kwesicelo sekhasimende

I-PCD

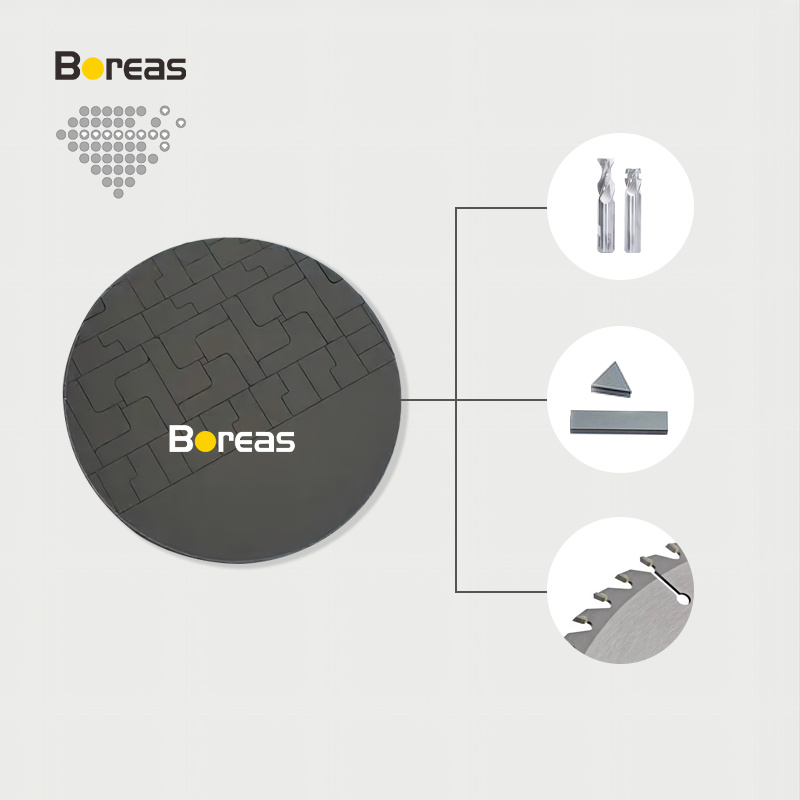

Izikhala zethuluzi lokusika le-PCD

- Izikhala zethuluzi lokusika le-PCD zenziwe ngendlela oyifisayo ukuze zihlangabezane nezidingo ezikhethekile noma izidingo zamakhasimende ethu.Izikhala zamathuluzi okusika e-PCD zisetshenziselwa kakhulu ukusika nokwenza izinsimbi nama-alloys angeyona i-ferrous njenge-SI/Al alloys, i-aluminium, ithusi kanye nama-alloys afanayo.Zibuye zisetshenziselwe umshini izinto ezingezona ezensimbi ezifana nokhuni, igraphite, izitsha zobumba, ipulasitiki, irabha nokunye, lapho kudingeka ukumelana nokuhuzuka okukhulu nokuphila isikhathi eside.

Izikhala zethuluzi lokusika le-PCD

I-aldeal for diamond saw blades, i-coring yokwakha kanye nokubhola, izisiki zedayimane zokunquma onqenqemeni, ukufaka kwe-PCD kokuphenduka nokugaya, izingcezu zokubhoboza idayimane zokubhoboza imigodi ezintweni eziyinhlanganisela namabhodi wesekethe, njll.

![[BRM-A] / Blocky Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

![[BRM-B] Uchungechunge Olucijile I-Micron Diamond powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

![[BRM-GC] I-High Purity Micron Diamond powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

![[BRM-GQ] I-Micron Diamond powder enamandla Aphakeme](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] I-Micron Diamond Powder yocingo lwedayimane](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] I-Micron Diamond Powder ye-PCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] Impushana Yedayimane Emise Kabusha](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] Impushana Yedayimane Yemeshi Echotshoziwe](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] Idayimane Lemeshi Elichotshoziwe Elihlaza](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)