0102030405

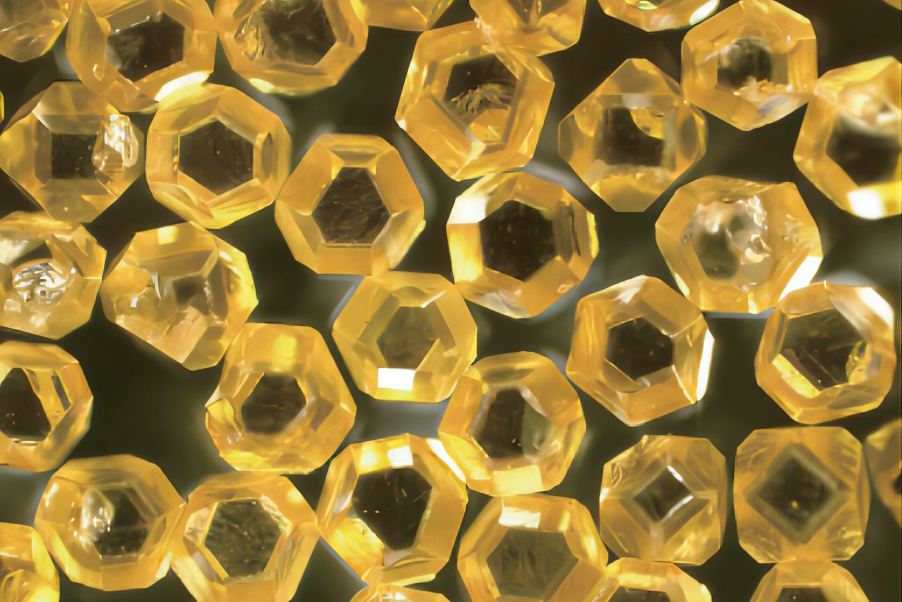

Idayimani yePolycrystalline

Iimpawu zokusebenza zePCD

(1) Ubunzima obuphezulu kunye nokumelana nokugqoka

I-PCD inobunzima obuphezulu, amandla acinezelayo aphezulu, i-thermal conductivity elungileyo kunye nokunganyangeki kokunxiba, inokuba kukusika ngesantya esiphezulu ukufumana ukuchaneka komatshini kunye nokusebenza kakuhle komatshini. iimpawu ezinjalo zezixhobo ze-PCD zichongwa yi-diamond crystal state, isakhiwo sinamandla okubopha okuqinileyo kunye nolwalathiso, ukuze idayimani ibe nobunzima obuphezulu kakhulu.

(2)Ukuchaneka okuphezulu komatshini

Izixhobo ze-PCD zine-coefficient ephantsi yokwandiswa kwe-thermal kunye ne-modulus ephezulu ye-elasticity, ngoko ke izixhobo azikho lula ukuba zikhubazeke ngexesha lenkqubo yokusika, kwaye kwangaxeshanye, amandla okusika kunye nobushushu bokusika kunokunciphisa ukuphucula ukuqina kwesixhobo kunye nokusika. ireyithi, ukuze ufumane umgangatho olungileyo womatshini.

(3) Ukuhanjiswa kwe-thermal ephezulu

I-thermal conductivity ye-PCD iphezulu kakhulu, ingcono kunesilivere, ithusi, kwaye iphezulu kakhulu kune-carbide ene-cemented jikelele, ngoko kulula ukutshabalalisa ubushushu kwinkqubo yokusika, kwaye ubushushu bokusika buphantsi.

Ingcaciso yeMveliso

(1) I-PCD kwizicelo zeemoto kunye ne-aerospace

Izixhobo zePCD kwibala leemoto zisetyenziselwa ikakhulu ukusetyenzwa kwengubo yepiston ye-injini, umngxuma wepin, ibhloko yesilinda, ibhokisi yegiya njalo njalo. Ngenxa yomxholo ophezulu we-silicon yala macandelo (ngaphezu kwe-10%), ubomi benkonzo yeemfuno zesixhobo, kunye nokuqina kwesixhobo se-PCD ngamaxesha angama-1-50 kwisixhobo se-carbide, kunokuqinisekisa ukuzinza kobukhulu bamacandelo, kwaye kunokuqinisekisa ukuzinza kobukhulu bamacandelo, kuphucula kakhulu isantya sokusika, ukusebenza kakuhle komatshini kunye nomgangatho womphezulu we-workpiece.

Kwintsimi ye-aerospace, ukusetyenziswa kwezixhobo ze-PCD zokucubungula i-aluminium alloy (AlSi2) intloko ye-cylinder, izinga lokusika liphezulu, kunye nobomi besixhobo kune-carbide ene-cemented ukuphucula malunga namaxesha angama-20, umgangatho ophezulu we-workpiece nawo uphuculwe kakhulu.

(2) I-PCD kwizicelo zeshishini lokulungisa iinkuni

Ukusetyenzwa kweenkuni kukwayindawo ebalulekileyo yosetyenziso lwezixhobo zePCD. Ngophuhliso olukhawulezayo lweepaneli zokwenziwa (i-medium density fiberboard, i-particleboard kunye ne-laminate flooring, njl.), ukukhawulezisa imfuno yezixhobo zokusika ezinzima kakhulu, ukwenzela ukuba izixhobo ze-PCD zithathe indawo yezixhobo zemithi zemveli kwimarike.

Uluhlu olungaphandle lwe-Al2O3 ye-laminate flooring i-abrasive kakhulu kwisixhobo se-carbide, kwaye ukusetyenziswa kwezixhobo ze-PCD kunokusombulula ngempumelelo le ngxaki. Ke ngoko, i-PCD kwishishini lokuchwela eyona marike iphambili iqinisiwe umgangatho odibeneyo kunye nobunzima obuphezulu be-fiberboard processing.

(3) I-PCD kwi-electronic processing industry applications

Ushishino lwe-elektroniki kwimveliso yeebhodi zesekethe eziprintiweyo zombane ngakumbi nangakumbi, isixhobo esisetyenziswayo ngokubanzi siya kuba ne-burr, echaphazela ukufakwa kunye nokubeka amacandelo ombane, kwaye yonke ibhodi yesekethe eprintiweyo ayintle; izixhobo zokusika i-carbide ekuqhubeni, ubomi obufutshane, isantya sokucotha, ukusebenza kakuhle, ukuchaneka kakubi komatshini. Ukusetyenziswa kwezixhobo zePCD, ukusebenza kakuhle okuphezulu, iindleko eziphantsi zokucwangcisa, zisetyenziswa ngokubanzi.

(4) I-PCD kwi-glass cutting and processing industry applications

Ivili lokusika elenziwe ngePCD lisetyenziselwa ukuchaneka okuphezulu, ukusika okukumgangatho ophezulu we-LCD izikrini zeemveliso zombane, kwaye kwangaxeshanye inokusika iglasi yokwakhiwa kunye nemoto. Ivili le-mandrel kunye ne-cutter zenziwe ngezinto ze-PCD, ezinoncedo lokuchaneka okuphezulu, ukuxhathisa ukunxiba, ukungaguquguquki okuhle, kunye nobomi benkonzo ephezulu ngaxeshanye, iyenza ibe yindawo efanelekileyo yeemela zeglasi eziqhelekileyo kunye namavili okusika iglasi ye-carbide.

(5) I-PCD kwi-composite materials industry applications

Ukusebenzisa izixhobo ze-PCD ukucubungula ii-glass fibers eziqiniswe iikompositi, ubomi bayo besixhobo bumalunga namaxesha angama-60 ezixhobo ze-carbide ze-cemented, i-piece piece processing cost yi-1/20 yezixhobo ze-carbide ze-cemented, kwaye ukuchaneka kokulungiswa kuphezulu kune-carbide ene-cemented.

PCD

-

LTM2200

Ubungakanani beenkozo

Ukunxiba ukuxhathisa

Ukuhanjiswa koMbane

Ukusila

1μm

IIIIII

IIIIIIIII

IIIIIIIII

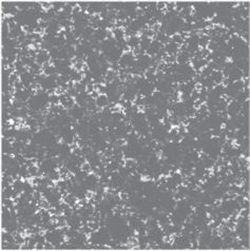

Iimpawu:1. I-1um yobungakanani obuqhelekileyo beenkozo.2. I-LTM2200'S i-ultra-fine grain structure ifanelekile kwizicelo apho ukugqitywa kwesipili kuyadingeka ngenxa yokubukhali kwayo okugqithisileyo.Izicelo: Ilungele ukugaya kunye nokusika i-aluminium alloys ye-silicon apho uxhathiso lwe-chip olugqithisileyo lufunekayo, kunye ne-machining titanium kunye ne-composites.

-

LTM004

Ubungakanani beenkozo

Ukunxiba ukuxhathisa

Ukuhanjiswa koMbane

Ukusila

4μm

IIIIIII

IIIIIII

IIIIIII

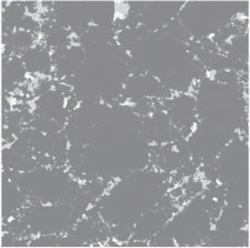

Iimpawu;1. 4um umndilili wobungakanani beenkozo.2. I-LTM004'S i-4-micron i-grain grain structure inikezela ukongezwa ekuhambiseni ibhalansi efanelekileyo phakathi kokusebenza kwesixhobo kunye nokuchasana nokukrala kunye neetshiphusi.Izicelo: Ilungele ukusika i-alloys ye-aluminiyam apho kufuneka ukugqiba okuphezulu komphezulu kunye nokumelana nokunxiba okuphezulu.

-

LTM10

Ubungakanani beenkozo

Ukunxiba ukuxhathisa

Ukuhanjiswa koMbane

Ukusila

10μm

IIIIIII

IIIIIII

IIIIIII

Iimpawu:1. 10μm ubungakanani obuqhelekileyo beenkozo.2. I-LTM10 yinqanaba le-PCD elisebenzayo lilungele izicelo ezininzi apho ulungelelwaniso oluhle lokuqina kunye nokumelana nokunxiba kuyadingeka.Izicelo: Elona bakala lifanelekileyo apho ukurhabaxa nokugqiba kwenziwa ngesixhobo esinye. Kucetyiswa kakhulu kumxholo ophantsi ukuya kophakathi wealloyi zealuminium.

-

LTM90

Ubungakanani beenkozo

Ukunxiba ukuxhathisa

Ukuhanjiswa koMbane

Ukusila

2-30μm

IIIIIIIII

IIIIII

IIIIII

Iimpawu;1. I-PCD yeemodeli ezininzi kunye nokudibanisa kwe-2μm ukuya kwi-30μm ubukhulu bengqolowa.2. Yenziwe ngemixube ekhethekileyo kunye nobushushu obukhethekileyo obuphezulu kunye noxinzelelo oluphezulu lweteknoloji.3. Imveliso inokumelana nokunxiba okuphezulu kakhulu kunye nokumelana nobushushu.Ukusetyenziswa: Iphumelele ekwenzeni i-silicon ephezulu ye-aluminium alloys, i-metal matrix composites, i-tungsten carbides.

PCD umgangatho imveliso series

PCD Composite Sheet Product Series kunye Cemented Carbide Layer | ||||||||||

Uhlobo | Idayimane (mm) UkuThimba koMaleko | Ukutyeba ngokupheleleyo (mm) | ||||||||

0.5 | 0.6 | 0.8 | 1.0 | 1.6 | 2.0 | 3.2 | 5.0 | 8.0 | ||

LTM2200 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM2200 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM004 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM004 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM10 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM10 | 0.5 |

|

| √ | √ | √ | √ | √ | √ |

|

LTM90 | 0.5 |

|

| √ | √ | √ | √ | √ | √ | √ |

Phawula:

1. Iphepha elihlanganisiweyo elinobukhulu obupheleleyo be-0.5,0.6, kunye ne-0.8 ayiboneleli kwiphepha elipheleleyo, kodwa linokubonelela nge-kinfe grain cutting okanye i-1/4 sheet;

2. Iphepha elihlanganisiweyo elinobunzima obupheleleyo be-1.0, 1.2 kunye ne-1.4 aliboneleli kwiphepha elipheleleyo, kodwa linokubonelela nge-kinfe grain cutting okanye i-1/2 sheet.

Iimveliso ezinobunzima obupheleleyo be-5.0 kunye ne-8.0 ziimveliso ezilungiselelwe.

Olunye ubungakanani kunye nezimbo zinokwenziwa ngokwezifiso ngokwesicelo somthengi

PCD

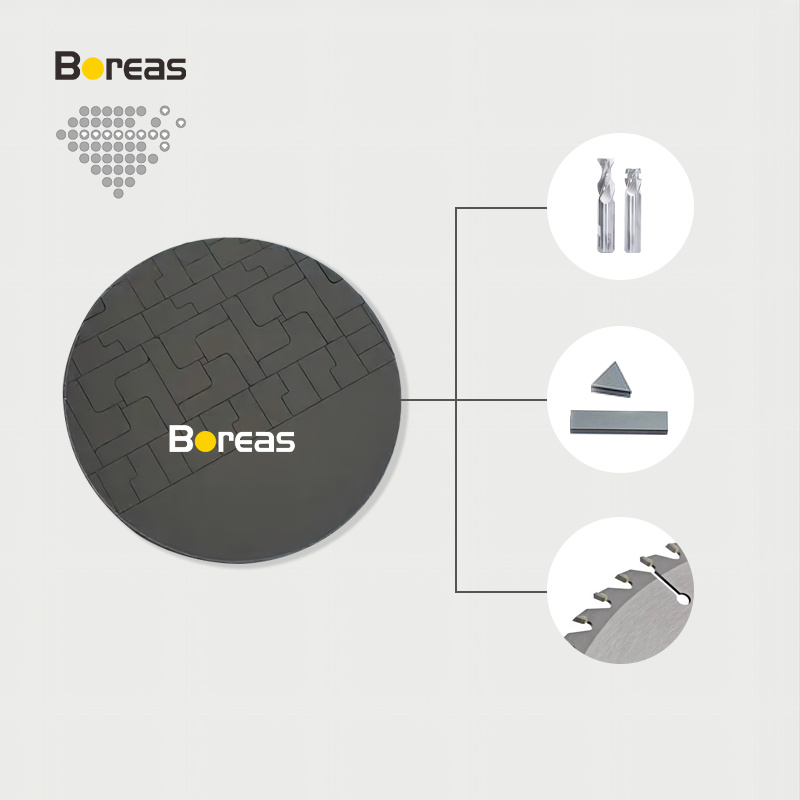

PCD ukusika izixhobo ezingenanto

- Izikhewu zesixhobo sokusika zePCD zilungiselelwe ukuhlangabezana neemfuno ezikhethekileyo okanye iimfuno zabathengi bethu.Izixhobo ze-PCD zokusika izixhobo zisetyenziselwa ukusika kunye nokwenza izixhobo zesinyithi ezingenayo i-ferrous kunye ne-alloys ezifana ne-SI / Al alloys, i-aluminium, ithusi kunye ne-alloys efanayo.Zikwasetyenziselwa umatshini wezinto ezingezizo ezentsimbi ezifana nemithi, igraphite, iiseramikhi, iplastiki, irabha njalo njalo, apho kufuneka ukuxhathisa okuphezulu kwe-abrasion kunye nobomi obude.

PCD ukusika izixhobo ezingenanto

ldeal for diamond saw blades, building coring and drilling, diamond cutters for edge-trimming, PCD installers for turning and milling, diamond drill bits for the hole-mining in composite materials and circuit boards, njl.

![[BRM-A] / Blocky Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

![[BRM-B] Uthotho oluloliweyo lweMicron yeDayimane yomgubo](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

![[BRM-GC] Umgubo weDayimane weMicron ococekileyo oPhezulu](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

![[BRM-GQ] Amandla aphezulu weDayimane yomgubo weMicron](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] iMicron Diamond Powder yocingo lweDayimane](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] iMicron Diamond Powder yePCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] Umgubo weDayimane oMilwe ngokutsha](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] Umgubo wedayimani ocoliweyo weMesh](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] Idayimani yoMnatha Otyumkileyo oLuhlaza](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)