0102030405

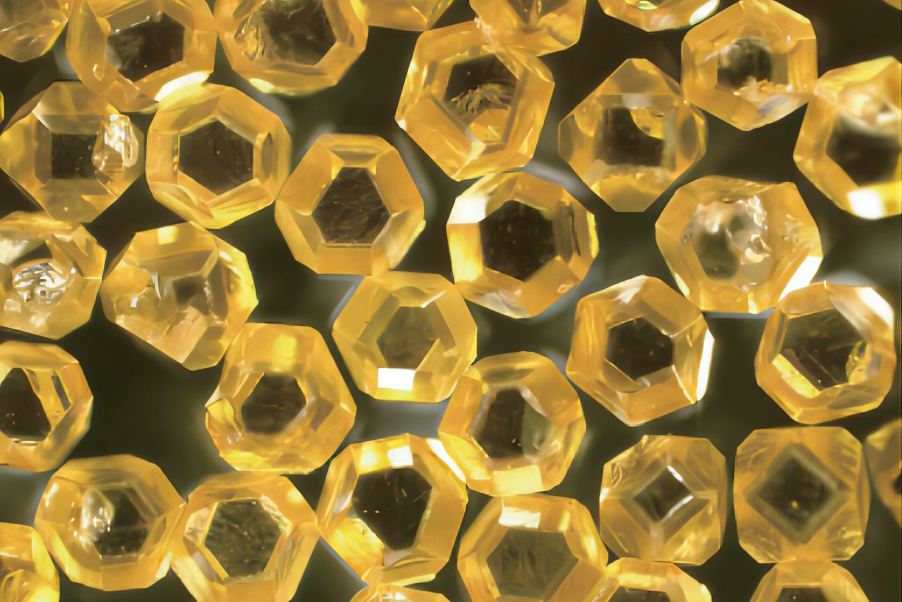

Polycrystalline Diamond

Litšobotsi tsa ts'ebetso ea PCD

(1) Boima bo phahameng le ho hanyetsa ho roala

PCD e na le boima bo phahameng, matla a khatello e phahameng, conductivity e ntle ea mocheso le ho hanyetsa ho roala, e ka ba ka har'a ho itšeha ka lebelo le phahameng ho fumana ho nepahala ha machining le ho sebetsa hantle ha mochini. litšoaneleho tse joalo tsa lisebelisoa tsa PCD li khethoa ke boemo ba kristale ea daemane, mohaho o na le matla a matla a tlamang le tataiso, e le hore daemane e be le boima bo phahameng haholo.

(2)Ho nepahala ha mochini o phahameng

Lisebelisoa tsa PCD li na le coefficient e tlase ea katoloso ea mocheso le modulus e phahameng ea elasticity, kahoo lisebelisoa ha li bonolo ho holofala nakong ea ts'ebetso ea ho itšeha, 'me ka nako e ts'oanang, matla a ho itšeha le mocheso oa ho itšeha o ka fokotsoa ho ntlafatsa ts'ebetso ea sesebelisoa le ho itšeha. tekanyo, e le hore u fumane sebaka se setle sa machining.

(3) High conductivity ea mocheso

Mocheso oa mocheso oa PCD o phahame haholo, o molemo ho feta silevera, koporo, 'me o phahame haholo ho feta carbide e tloaelehileng ea samente, kahoo ho bonolo ho senya mocheso nakong ea ho itšeha,' me mocheso oa ho itšeha o tlaase.

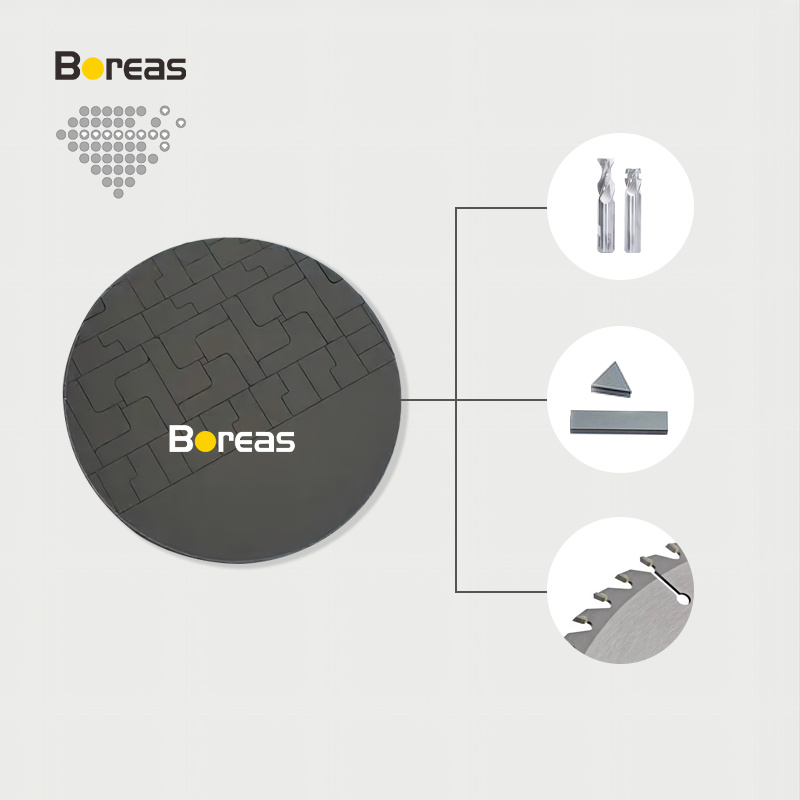

Tlhaloso ea Sehlahisoa

(1) PCD lits'ebetsong tsa likoloi le tsa sefofane

Lisebelisoa tsa PCD lebaleng la likoloi li sebelisoa haholo bakeng sa ho lokisa moleka oa piston ea enjene, lesoba la pin, cylinder block, gearbox joalo-joalo. Ka lebaka la likarolo tse phahameng tsa silicon tsa likarolo tsena (tse fetang 10%), bophelo ba tšebeletso ea litlhoko tsa lisebelisoa, le PCD sesebelisoa sa nako e telele ke makhetlo a 1-50 ho sesebelisoa sa carbide, se ka netefatsa botsitso ba boholo ba likarolo, 'me se ka etsa ntlafatsa haholo lebelo la ho itšeha, katleho ea machining le boleng ba holim'a mochini oa mosebetsi.

Sebakeng sa sefofane, tšebeliso ea lisebelisoa tsa PCD tse sebetsanang le aluminium alloy (AlSi2) hlooho ea cylinder, sekhahla sa ho itšeha se phahame, le bophelo ba lisebelisoa ho feta carbide e entsoeng ka samente ho ntlafatsa ka makhetlo a ka bang 20, boleng ba holim'a mochini oa mosebetsi le bona bo ntlafatsoa haholo.

(2) PCD lits'ebetsong tsa indasteri ea ho lokisa lehong

Ho sebetsa ha lehong hape ke sebaka sa bohlokoa sa lisebelisoa tsa lisebelisoa tsa PCD. Ka nts'etsopele e potlakileng ea liphanele tsa maiketsetso (li-medium density fiberboard, particleboard le laminate flooring, joalo-joalo), ho potlakisa tlhokahalo ea lisebelisoa tsa ho itšeha tse thata haholo, e le hore lisebelisoa tsa PCD butle-butle li nke sebaka sa lisebelisoa tsa khale tsa mapolanka 'marakeng.

Lera le ka ntle la Al2O3 la fatše la laminate le senya haholo sesebelisoa sa carbide, 'me tšebeliso ea lisebelisoa tsa PCD e ka rarolla bothata bona ka katleho. Ka hona, PCD 'marakeng oa mantlha oa indasteri ea mapolanka e matlafalitsoe ka mokatong o kopaneng le ts'ebetso e phahameng ea fiberboard e thata.

(3) PCD lits'ebetsong tsa indasteri ea ts'ebetso ea elektroniki

Indasteri ea lisebelisoa tsa elektronike tlhahisong ea liboto tsa potoloho tsa motlakase tse hatisitsoeng li batla li le boima le ho feta, sesebelisoa se akaretsang se sebelisoang se tla ba le burr, se amang ho kenngoa le ho behoa ha likarolo tsa motlakase, 'me boto ea potoloho eohle e hatisitsoeng ha e ntle; lisebelisoa tsa ho itšeha ha carbide nakong ea ts'ebetso, bophelo bo khuts'oane, lebelo le liehang la ts'ebetso, ts'ebetso e tlase, ho nepahala ha machining. Tšebeliso ea lisebelisoa tsa PCD, ts'ebetso e phahameng ea ts'ebetso, litšenyehelo tse tlase tsa ts'ebetso, tse sebelisoang haholo.

(4) PCD ts'ebetsong ea indasteri ea ho itšeha le ho e lokisa

Cutter wheel e entsoeng ka PCD e sebelisoa haholo-holo bakeng sa ho itšeha ka mokhoa o phahameng, oa boleng bo phahameng ba lihlahisoa tsa elektroniki tsa LCD, 'me ka nako e ts'oanang e ka khaola likhalase bakeng sa kaho le koloi. Lebili la mandrel le cutter le entsoe ka thepa ea PCD, e nang le melemo ea ho sebetsa ka mokhoa o nepahetseng, ho hanyetsa ho roala, ho tsitsisa hantle, le bophelo ba tšebeletso e phahameng ka nako e le 'ngoe, e leng se etsang hore e be sebaka se loketseng bakeng sa lithipa tse tloaelehileng tsa khalase le mabili a sehang likhalase tsa carbide.

(5) PCD lits'ebetsong tsa indasteri ea lisebelisoa tse kopaneng

U sebelisa lisebelisoa tsa PCD ho sebetsana le lisebelisoa tse matlafalitsoeng tsa khalase, bophelo ba lisebelisoa tsa eona bo ka ba makhetlo a 60 ho feta lisebelisoa tsa carbide tse entsoeng ka samente, theko e le 'ngoe ea lisebelisoa tsa carbide ke 1/20 ea lisebelisoa tse entsoeng ka samente,' me ho nepahala ha ho sebetsa ho phahame ho feta carbide e entsoeng ka samente.

PCD

-

LTM2200

Boholo ba lijo-thollo

Apara khanyetso

Motlakase Conductivity

Ho sila

1 μm

IIIIII

IIIIIIIII

IIIIIIIII

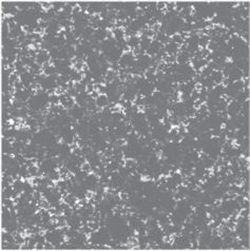

Litšobotsi:1. 1um karolelano ea boholo ba lijo-thollo.2. LTM2200'S sebopeho sa lijo-thollo tse ntle ka ho fetesisa se loketse lits'ebetso moo liipone li hlokahalang ka lebaka la bohale ba eona bo feteletseng.Lisebelisoa: E loketse bakeng sa ho sila le ho seha li-alloys tsa silicon ea aluminium moo ho hlokahalang khanyetso e feteletseng ea chip, hape bakeng sa machining titanium le composite.

-

LTM004

Boholo ba lijo-thollo

Apara khanyetso

Motlakase Conductivity

Ho sila

4 μm

IIIIIIII

IIIIIII

IIIIIII

Litšobotsi;1. 4um karolelano ea boholo ba lijo-thollo.2. LTM004'S 4-micron sebopeho se setle sa lijo-thollo se fana ka tlatsetso ea ho fana ka tekanyo e nepahetseng pakeng tsa ts'ebetso ea lisebelisoa le ho hanyetsa ho senya le li-chips.Lisebelisoa: E loketse bakeng sa ho seha li-alloys tsa aluminium moo ho hlokahalang hore ho be le sepakapaka se phahameng hammoho le khanyetso e phahameng ea ho apara.

-

LTM10

Boholo ba lijo-thollo

Apara khanyetso

Motlakase Conductivity

Ho sila

10μm

IIIIIIII

IIIIIII

IIIIIIII

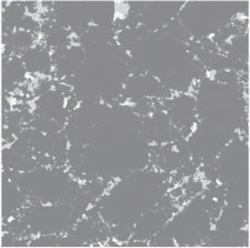

Litšobotsi:1. 10μm karolelano ea boholo ba lijo-thollo.2. LTM10 ke boemo ba PCD bo sebetsang hantle bakeng sa lits'ebetso tse ngata moo ho hlokahalang ho leka-lekanya ho thatafala le ho hanyetsa ho apara.Likopo: Kereiti e loketseng moo ho hlaka le ho phethela ho etsoang ka sesebelisoa se le seng. E khothalelitsoe haholo bakeng sa li-alloys tsa aluminium tse tlase ho isa ho tse mahareng.

-

LTM90

Boholo ba lijo-thollo

Apara khanyetso

Motlakase Conductivity

Ho sila

2-30μm

IIIIIIIII

IIIIII

IIIIII

Litšobotsi;1. PCD ea mefuta e mengata e nang le motsoako oa 2μm ho 30μm boholo ba lijo-thollo.2. E entsoe ka metsoako e ikhethang le mocheso o khethehileng o phahameng le theknoloji ea ho kopanya khatello e phahameng.3. Sehlahisoa se na le khanyetso e phahameng haholo ea ho apara le ho hanyetsa mocheso.Likopo: E atlehile ho etsa machining a lialloys tse phahameng tsa silicon aluminium, metsoako ea tšepe ea matrix, tungsten carbides.

Letoto la lihlahisoa tse tloaelehileng tsa PCD

PCD Composite Sheet Product Series e nang le Cemented Carbide Layer | ||||||||||

Mofuta | Taemane (mm) Botenya ba Lera | Kakaretso ea Botenya (mm) | ||||||||

0.5 | 0.6 | 0.8 | 1.0 | 1.6 | 2.0 | 3.2 | 5.0 | 8.0 | ||

LTM2200 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM2200 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM004 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM004 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM10 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM10 | 0.5 |

|

| √ | √ | √ | √ | √ | √ |

|

LTM90 | 0.5 |

|

| √ | √ | √ | √ | √ | √ | √ |

Hlokomela:

1. Letlapa le kopantseng le nang le botenya bohle ba 0.5,0.6, le 0.8 ha le fane ka lakane eohle, empa le ka fana ka kinfe lijo-thollo seha kapa 1/4 lakane;

2. Letlapa le kopantsoeng le botenya bohle ba 1.0, 1.2 le 1.4 ha le fane ka lakane eohle, empa le ka fana ka seha sa lijo-thollo tsa kinfe kapa 1/2 lakane.

Lihlahisoa tse nang le botenya bohle ba 5.0 le 8.0 ke lihlahisoa tse ikhethileng.

Mefuta e meng ea boholo le mekhoa e ka etsoa ho latela kopo ea moreki

PCD

Likheo tsa lisebelisoa tsa ho itšeha tsa PCD

- Likheo tsa lisebelisoa tsa ho itšeha tsa PCD li hlophisehe ho fihlela litlhoko kapa litlhoko tse khethehileng tsa bareki ba rona.Likheo tsa lisebelisoa tsa ho itšeha tsa PCD li sebelisoa haholo-holo bakeng sa ho seha le ho lokisa litšepe tse se nang ferrous le lialloys tse kang li-alloys tsa SI/Al, aluminium, koporo le li-alloys tse tšoanang.Li boetse li sebelisetsoa ho etsa mochini oa lisebelisoa tse seng tsa tšepe tse kang lehong, graphite, ceramics, polasetiki, rabara joalo-joalo, moo ho hanyetsanang ho phahameng le ho phela nako e telele ho hlokahalang.

Likheo tsa lisebelisoa tsa ho itšeha tsa PCD

ldeal bakeng sa li-blades tsa daemane, li-coring tsa kaho le ho cheka, lithapo tsa litaemane bakeng sa ho fokotsa moeli, li-PCD tse kentsoeng bakeng sa ho phethoha le ho sila, likotoana tsa ho cheka daemane bakeng sa ho phunya masoba ka thepa e kopaneng le liboto tsa potoloho, jj.

![[BRM-A] / Blocky Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

![[BRM-B] Letoto le Hlōletsoeng la Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

![[BRM-GC] Phofo ea Taemane e Phahameng ea Purity Micron](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

![[BRM-GQ] Phofo ea Taemane ea Micron e Matla a Phahameng](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] Phofo ea Taemane ea Micron bakeng sa Mohala oa Taemane](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] Micron Diamond Powder bakeng sa PCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] Phofo ea Taemane e Bopehileng Bocha](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] Phofo ea Taemane e Hatetsoeng ea Mesh](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] Taemane e Krithetsoeng ea Mesh e Tala](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)