0102030405

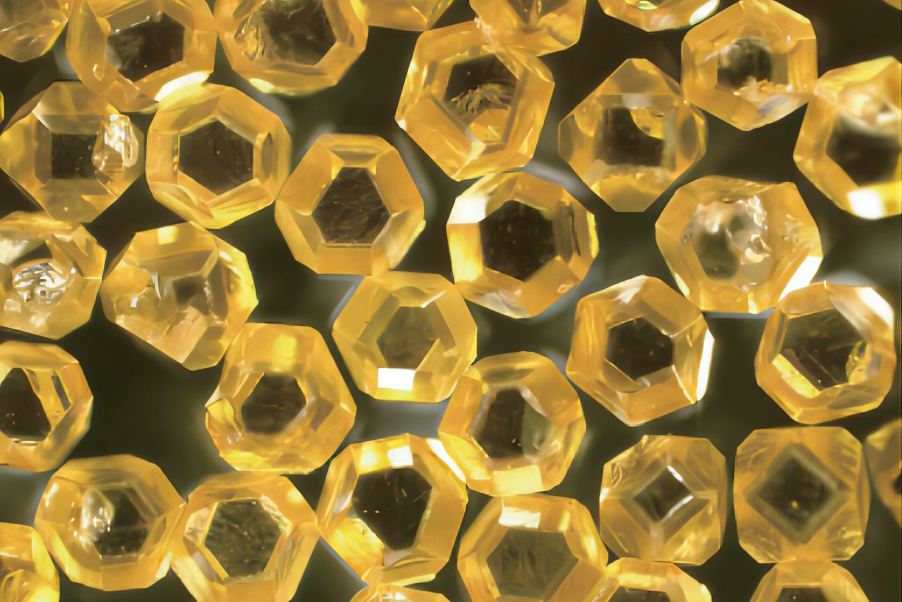

Polycrystalline diamond

Njirimara arụmọrụ nke PCD

(1) Akwa ike ike na iyi nguzogide

PCD nwere isi ike dị elu, ike mkpakọ dị elu, ezigbo conductivity thermal na eyi nguzogide, nwere ike ịdị na ịkpụ ọsọ ọsọ iji nweta izi ezi machining na nrụpụta ọrụ. A na-ekpebi njirimara ndị dị otú ahụ nke ngwaọrụ PCD site na steeti kristal diamond, ihe owuwu ahụ nwere ike na-ejikọta ike na ntụziaka, nke mere na diamond nwere ike dị elu.

(2)Izi ezi machining dị elu

Ngwá ọrụ PCD nwere ọnụ ọgụgụ dị ala nke mgbasawanye ọkụ na modul nke ịdị elu nke ịdị elu, ya mere ngwá ọrụ adịghị mfe ịmegharị n'oge usoro ịkpụ, ma n'otu oge ahụ, ike ịkpụ na ịkpụ okpomọkụ nwere ike ibelata iji meziwanye ike na ịcha ngwá ọrụ. ọnụego, ka e wee nweta ezigbo machining elu.

(3) High thermal conductivity

Thermal conductivity nke PCD dị nnọọ elu, dị mma karịa ọlaọcha, ọla kọpa, na ọtụtụ elu karịa general cemented carbide, n'ihi ya, ọ dị mfe igbasa okpomọkụ na ọnwụ usoro, na ọnwụ okpomọkụ dị ala.

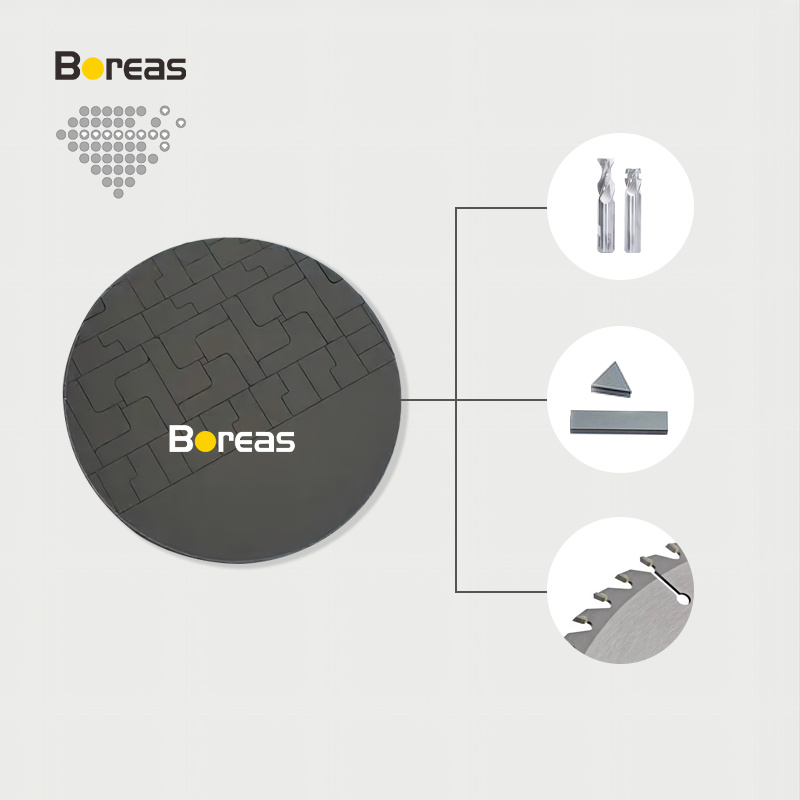

nkọwa ngwaahịa

(1) PCD n'ime ụgbọ ala na ngwa ikuku

A na-ejikarị ngwaọrụ PCD na mpaghara ụgbọ ala eme ihe maka nhazi sket nke piston engine, oghere pin, ngọngọ cylinder, igbe gear na ihe ndị ọzọ. N'ihi ọdịnaya silicon dị elu nke akụkụ ndị a (karịa 10%), ndụ ọrụ nke ngwá ọrụ chọrọ, na PCD ngwá ọrụ ogologo oge bụ 1-50 ugboro carbide ngwá ọrụ, nwere ike hụ na nkwụsi ike nke size nke akụkụ, na ike. ukwuu melite ọnwụ ọsọ, machining arụmọrụ na elu àgwà nke workpiece.

Na aerospace ubi, ojiji nke PCD ngwaọrụ nhazi aluminum alloy (AlSi2) cylinder isi, ọnwụ ọnụego bụ elu, na ngwá ọrụ ndụ karịa cemented carbide ka mma banyere 20 ugboro, elu àgwà nke workpiece na-ukwuu mma.

(2) PCD na ngwa ụlọ ọrụ nhazi osisi

Nhazi osisi bụkwa akụkụ dị mkpa nke ngwa ngwa PCD. Site na mmepe ngwa ngwa nke akụkụ sịntetik (ọkara njupụta fiberboard, particleboard na laminate flooring, wdg), na-eme ka ọchịchọ maka ngwa ịkpụ ihe siri ike, nke mere na ngwaọrụ PCD jiri nwayọ dochie ngwa ọrụ osisi ọdịnala n'ahịa.

Oghere dị n'elu nke Al2O3 nke laminate flooring bụ ihe na-adịghị mma na ngwá ọrụ carbide, na iji PCD ngwaọrụ nwere ike dozie nsogbu a nke ọma. Ya mere, PCD n'ime isi ahịa ụlọ ọrụ na-arụ ọrụ osisi na-emesiwanye ala ala mejupụtara yana nhazi fiberboard siri ike.

(3) PCD na ngwa ụlọ ọrụ nhazi eletrọnịkị

Ụlọ ọrụ na-emepụta ngwá electronic na-emepụta ihe ndị na-emepụta ihe na-emepụta ihe na-achọsi ike karị, ngwá ọrụ n'ozuzu nke a na-eji eme ihe ga-enwe burr, na-emetụta ntinye na ntinye nke ihe eletriki eletrik, na akụkụ dum nke e biri ebi adịghị mma; carbide ịkpụ ngwaọrụ na nhazi, obere ndụ, ngwa ngwa nhazi ọsọ, ala arụmọrụ, adịghị mma machining ziri ezi. Ojiji nke PCD ngwaọrụ, nhazi nhazi dị elu, ọnụ ahịa nhazi dị ala, na-ejikarị eme ihe.

(4) PCD na iko ịkpụ na nhazi ụlọ ọrụ ngwa

Cutter wheel mere nke PCD na-bụ-eji maka elu-nkenke, elu-edu ọnwụ nke LCD meziri nke electronic ngwaahịa, na n'otu oge ahụ nwere ike bee iko maka ewu na ụgbọala. A na-eji ihe PCD mee mandrel na cutter wheel, nke nwere uru nke nhazi nhazi dị elu, na-eyi nkwụsi ike, nkwụsi ike dị mma, na ndụ ọrụ dị elu n'otu oge ahụ, na-eme ka ọ bụrụ ihe dị mma dochie anya mma iko nkịtị na wiil carbide glass cutter wheel.

(5) PCD na ngwa ụlọ ọrụ ihe mejupụtara

Iji ngwaọrụ PCD hazie ihe mejupụtara enyo enyo fiber mesiri ike, ndụ ngwá ọrụ ya dị ihe dị ka ugboro 60 nke ngwaọrụ carbide cemented, ọnụ ahịa nhazi otu mpempe akwụkwọ bụ 1/20 nke ngwaọrụ carbide cimented, na nhazi nhazi dị elu karịa nke carbide cemented.

PCD

-

LTM2200

Nha ọka

Yiri nguzogide

Igwe ọkụ eletrik

Iri ihe

1μm

IIIIII

IIIIIII

IIIIIII

Njirimara:1. 1um nkezi nha ọka.2. LTM2200'S ultra-mma ọka Ọdịdị bụ adabara ngwa ebe mirror imecha na-achọrọ n'ihi na ya oké ọnụ sharpness.Ngwa: Ọ dị mma maka egwe ọka na ịkpụ aluminom silicon alloys ebe a na-achọ oke mgbawa mgbawa, bụkwa maka igwe titanium na ihe mejupụtara.

-

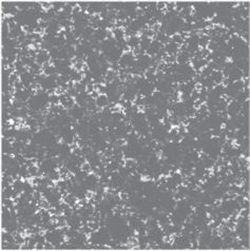

LTM004

Nha ọka

Yiri nguzogide

Igwe ọkụ eletrik

Iri ihe

4μm

IIIIIII

IIIIIII

IIIIIII

Àgwà;1. 4um nkezi nha ọka.2. LTM004'S 4-micron ezi ọka Ọdịdị na-enye mgbakwunye na-ebuga kacha itule n'etiti ngwá ọrụ arụmọrụ na iguzogide abrasions na ibe.Ngwa: Ezigbo maka ịcha aluminum alloys ebe elu elu imecha chọrọ n'akụkụ elu eyi iguzogide.

-

LTM10

Nha ọka

Yiri nguzogide

Igwe ọkụ eletrik

Iri ihe

10μm

IIIIIII

IIIIIII

IIIIIII

Njirimara:1. 10μm nkezi nha ọka.2. LTM10 bụ workhorse PCD ọkwa dị mma maka ọtụtụ ngwa ebe ezi itule nke siri ike na eyi iguzogide a chọrọ.Ngwa: The ezigbo ọkwa ebe roughing na finishing na-arụ na otu ngwá ọrụ. Akwadoro nke ukwuu maka obere na ọkara ọdịnaya aluminum alloys.

-

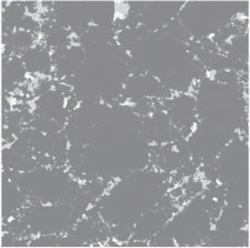

LTM90

Nha ọka

Yiri nguzogide

Igwe ọkụ eletrik

Iri ihe

2-30μm

IIIIIIII

IIIIII

IIIIII

Àgwà;1. PCD multi-model na ngwakọta nke 2μm na 30μm ọka nha.2. Ọ na-mere nke pụrụ iche ngwakọta na pụrụ iche elu okpomọkụ na elu mgbali njikọ technology.3. Ngwaahịa ahụ nwere oke mkpuchi mkpuchi na-eguzogide okpomọkụ.Ngwa: Na-eme nke ọma n'ịrụpụta silicon aluminum alloys, metal matrix composites, tungsten carbides.

Usoro ngwaahịa ọkọlọtọ PCD

PCD Composite Mpempe akwụkwọ Ngwaahịa Series nwere cemented Carbide Layer | ||||||||||

Ụdị | diamond (mm) Echiche oyi akwa | Mkpokọta ọkpụrụkpụ (mm) | ||||||||

0.5 | 0.6 | 0.8 | 1.0 | 1.6 | 2.0 | 3.2 | 5.0 | 8.0 | ||

LTM2200 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM2200 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM004 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM004 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM10 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM10 | 0.5 |

|

| √ | √ | √ | √ | √ | √ |

|

LTM90 | 0.5 |

|

| √ | √ | √ | √ | √ | √ | √ |

Mara:

1. Mpempe akwụkwọ mpempe akwụkwọ na ngụkọta nke 0.5,0.6, na 0.8 adịghị enye mpempe akwụkwọ dum, ma ọ nwere ike inye mkpụrụ ọka kinfe ma ọ bụ mpempe akwụkwọ 1/4;

2. Mpempe akwụkwọ mpempe akwụkwọ na ngụkọta nke 1.0, 1.2 na 1.4 adịghị enye akwụkwọ ahụ dum, ma ọ nwere ike inye mkpụrụ ọka kinfe ma ọ bụ 1/2 mpempe akwụkwọ.

Ngwaahịa na ngụkọta ọkpụrụkpụ nke 5.0 na 8.0 bụ ahaziri ngwaahịa.

Enwere ike ịhazi nha na ụdị ndị ọzọ dịka arịrịọ ndị ahịa si dị

PCD

PCD ịkpụ ngwá ọrụ oghere

- PCD ọnwụ ngwá ọrụ oghere ga-ahaziri izute ndị ahịa anyị mkpa pụrụ iche ma ọ bụ chọrọ.A na-ejikarị ihe eji egbutu PCD eme ihe maka ịkpụ na ịkpụpụta ọla ndị na-abụghị igwe na alloys dị ka SI / Al alloys, aluminium, ọla kọpa na alloys ndị yiri ya.A na-ejikwa ha na-emepụta ihe ndị na-abụghị ọla dị ka osisi, graphite, ceramics, plastic, roba na ihe ndị ọzọ, ebe a chọrọ nnukwu ihe mgbochi na ogologo ndụ.

PCD ịkpụ ngwá ọrụ oghere

ldeal maka diamond hụrụ agụba, mwube coring na mkpọpu ihe, diamond cutters maka ihu-mbelata, PCD ntinye maka ịtụgharị na-egwe ọka, diamond drill bits maka oghere-egwupụta ihe n'ime ihe mejupụtara na bọọdụ sekit, wdg.

![[BRM-A] / Blocky Series Micron Diamond ntụ ntụ](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

![[BRM-B] Usoro Micron Diamond ntụ ntụ](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

![[BRM-GC] Ntụ ntụ diamond dị ọcha dị elu](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

![[BRM-GQ] Ike Micron Diamond ntụ ntụ](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] Micron diamond ntụ ntụ maka waya diamond](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] Micron Diamond ntụ ntụ maka PCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] ntụ ntụ diamond kpụgharịrị](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] ntụ ntụ ntụ ntụ diamond gwepịara](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] diamond ntupu ahịhịa ahịhịa juru](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)