0102 ib0304 ib05

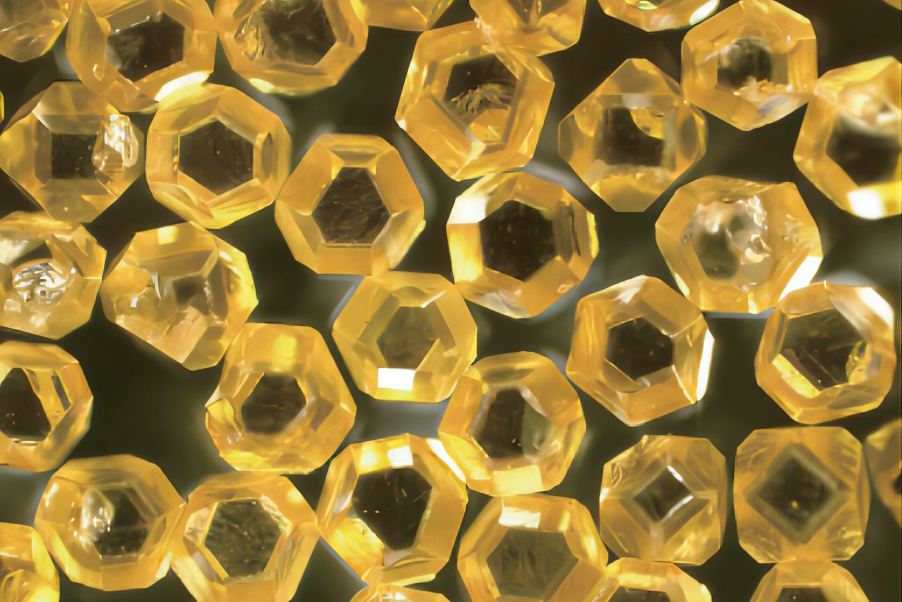

Polycrystalline pob zeb diamond

Kev ua tau zoo ntawm PCD

(1) High hardness thiab hnav tsis kam

PCD muaj siab hardness, siab compressive zog, zoo thermal conductivity thiab hnav tsis kam, yuav ua tau nyob rau hauv high-ceev txiav kom tau siab machining raug thiab machining efficiency. xws li cov yam ntxwv ntawm PCD cov cuab yeej yog txiav txim los ntawm lub pob zeb diamond siv lead ua lub xeev, cov qauv muaj ib tug muaj zog binding quab yuam thiab directionality, yog li ntawd lub pob zeb diamond muaj ib tug heev hardness.

(2) High machining raug

PCD cov cuab yeej muaj qis coefficient ntawm thermal expansion thiab siab modulus ntawm elasticity, yog li cov cuab yeej tsis yooj yim rau deformed thaum lub sij hawm txiav, thiab tib lub sij hawm, txiav quab yuam thiab txiav kub yuav txo tau los txhim kho cov cuab yeej durability thiab txiav. tus nqi, thiaj li yuav tau zoo machining nto.

(3) High thermal conductivity

Lub thermal conductivity ntawm PCD yog siab heev, zoo dua cov nyiaj, tooj liab, thiab ntau dua li cov cemented carbide, yog li nws yooj yim rau dissipate tshav kub nyob rau hauv cov txheej txheem txiav, thiab txiav kub yog qis dua.

cov khoom piav qhia

(1) PCD hauv kev siv tsheb thiab aerospace

PCD cov cuab yeej hauv tsheb yog tsuas yog siv rau kev ua cov tiab ntawm lub cav piston, tus pin qhov, lub tog raj kheej thaiv, gearbox thiab lwm yam. Vim yog cov ntsiab lus ntawm silicon siab ntawm cov khoom no (ntau dua 10%), kev pabcuam lub neej ntawm cov cuab yeej siv, thiab PCD cov cuab yeej siv tau ntev yog 1-50 npaug ntawm cov cuab yeej carbide, tuaj yeem ua kom ruaj khov ntawm qhov loj ntawm cov khoom, thiab tuaj yeem ua tau. zoo heev txhim kho qhov txiav ceev, machining efficiency thiab nto zoo ntawm lub workpiece.

Hauv kev lag luam aerospace, kev siv PCD cov cuab yeej ua aluminium alloy (AlSi2) lub tog raj kheej lub taub hau, txiav tus nqi siab dua, thiab cov cuab yeej lub neej tshaj li cemented carbide los txhim kho txog 20 npaug, qhov zoo ntawm cov khoom ua haujlwm kuj zoo heev.

(2) PCD nyob rau hauv daim ntawv thov kev lag luam ntoo

Kev ua ntoo kuj yog ib qho tseem ceeb ntawm kev siv cov cuab yeej PCD. Nrog rau kev loj hlob sai ntawm cov khoom vaj huam sib luag (nruab nrab ntom ntom fiberboard, particleboard thiab laminate flooring, thiab lwm yam), ua kom nrawm rau qhov kev thov rau cov cuab yeej siv tawv tawv, kom cov cuab yeej PCD maj mam hloov cov khoom siv ntoo hauv kev ua lag luam.

Cov txheej txheej sab nraud ntawm Al2O3 ntawm laminate flooring yog abrasive heev rau cov cuab yeej carbide, thiab kev siv cov cuab yeej PCD tuaj yeem daws qhov teeb meem no zoo. Yog li ntawd, PCD nyob rau hauv kev lag luam woodworking lub lag luam tseem ceeb yog ntxiv dag zog flooring thiab siab hardness fiberboard ua.

(3) PCD hauv kev siv hluav taws xob ua lag luam

Kev lag luam hluav taws xob hauv kev tsim hluav taws xob luam tawm hluav taws xob ntau dua thiab xav tau ntau dua, cov cuab yeej siv dav dav hauv kev siv yuav muaj burr, cuam tshuam rau kev teeb tsa thiab qhov chaw ntawm cov khoom siv hluav taws xob, thiab tag nrho cov ntawv luam tawm Circuit Board tsis zoo nkauj; carbide txiav cov cuab yeej hauv kev ua haujlwm, lub neej luv luv, ua haujlwm qeeb, kev ua haujlwm qis, tsis zoo machining raug. Kev siv cov cuab yeej PCD, kev ua haujlwm siab, cov nqi ua haujlwm tsawg, siv ntau dua.

(4) PCD nyob rau hauv cov iav txiav thiab ua cov ntawv thov kev lag luam

Cutter log ua los ntawm PCD yog tsuas yog siv rau high-precision, high-zoo txiav cov ntxaij vab tshaus LCD ntawm cov khoom siv hluav taws xob, thiab tib lub sij hawm tuaj yeem txiav iav rau kev tsim kho thiab tsheb. Lub mandrel thiab cutter log yog ua los ntawm cov khoom siv PCD, uas muaj qhov zoo ntawm kev ua haujlwm siab, hnav tsis kam, zoo sib xws, thiab lub neej ua haujlwm siab nyob rau tib lub sijhawm, ua rau nws zoo tagnrho hloov rau cov iav riam thiab carbide iav cutter log.

(5) PCD hauv kev lag luam cov ntaub ntawv sib xyaw

Siv cov cuab yeej PCD los ua cov iav fiber ntau ntxiv, nws lub neej cuab yeej yog li 60 npaug ntawm cov cuab yeej cemented carbide, tus nqi ua haujlwm ib zaug yog 1/20 ntawm cov cuab yeej cemented carbide, thiab kev ua haujlwm raug siab dua li cov cemented carbide.

PCD

-

LWM 2200

Cov qoob loo loj

Hnav tsis kam

Hluav taws xob conductivity

Grindability

1m ua

Ib IIIIII

IIIIIIIIIIII

IIIIIIIIIIII

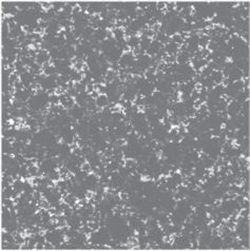

Yam ntxwv:1.1um nruab nrab grain loj.2. LTM2200'S ultra-fine grain qauv yog tsim rau daim ntaub ntawv uas yuav tsum tau daim iav tiav vim nws cov ntug heev sharpness.Daim ntaub ntawv: Zoo tagnrho rau milling thiab txiav aluminium silicon alloys qhov twg yuav tsum tau muaj nti tsis kam, kuj yog rau machining titanium thiab composites.

-

LWM 004

Cov qoob loo loj

Hnav tsis kam

Hluav taws xob conductivity

Grindability

4m ua

IIIIIIIII

IIIIIIIII

IIIIIIIII

Cov yam ntxwv;1. 4um nruab nrab grain loj.2. LTM004'S 4-micron nplua nplej qauv muaj cov khoom ntxiv rau kev xa cov khoom zoo tshaj plaws ntawm cov cuab yeej kev ua tau zoo thiab tsis kam ua kom puas thiab chips.Daim ntaub ntawv: Qhov zoo tshaj plaws rau kev txiav ntawm aluminium alloys qhov chaw siab saum npoo yuav tsum tau ua nrog kev hnav siab dua.

-

LTM 10

Cov qoob loo loj

Hnav tsis kam

Hluav taws xob conductivity

Grindability

10m ua

IIIIIIIII

IIIIIIIII

IIIIIIIII

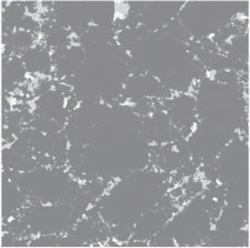

Yam ntxwv:1. 10μm nruab nrab grain loj.2. LTM10 yog qib PCD ua haujlwm zoo rau ntau daim ntawv thov uas yuav tsum muaj qhov sib npaug zoo ntawm cov tawv thiab hnav tsis kam.Daim ntawv thov: Cov qib zoo tshaj plaws uas roughing thiab tiav yog ua nrog ib lub cuab yeej. Pom zoo rau cov ntsiab lus qis rau nruab nrab aluminium alloys.

-

LTM 90

Cov qoob loo loj

Hnav tsis kam

Hluav taws xob conductivity

Grindability

2-30 m²

IIIIIIIIIIII

Ib IIIIII

Ib IIIIII

Cov yam ntxwv;1. Muaj ntau hom PCD nrog kev sib xyaw ua ke ntawm 2μm mus rau 30μm nplej ntau thiab tsawg.2. Nws yog ua los ntawm cov khoom sib xyaw tshwj xeeb thiab tshwj xeeb kub thiab kub siab synthesis technology.3. Cov khoom muaj kev hnav tsis kam thiab kub ua hauj.Daim ntaub ntawv: Ua tau zoo nyob rau hauv machining ntawm siab silicon aluminium alloys, hlau matrix composites, tungsten carbides.

PCD txheem khoom series

PCD Composite Sheet Khoom Series nrog Cemented Carbide Txheej | ||||||||||

Hom | Pob zeb diamond (mm) Txheej Thinckness | Tag nrho Thickness (mm) | ||||||||

0.5 | 0.6 | 0.8 ua | 1.0 | 1.6 | 2.0 | 3.2 | 5.0 | 8.0 ib | ||

LWM 2200 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LWM 2200 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LWM 004 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LWM 004 | 0.5 |

|

| √ | √ | √ | √ | √ |

|

|

LTM 10 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

|

|

LTM 10 | 0.5 |

|

| √ | √ | √ | √ | √ | √ |

|

LTM 90 | 0.5 |

|

| √ | √ | √ | √ | √ | √ | √ |

Nco tseg:

1. Daim ntawv sib xyaw nrog tag nrho cov tuab ntawm 0.5,0.6, thiab 0.8 tsis muab tag nrho daim ntawv, tab sis tuaj yeem muab kinfe nplej txiav lossis 1/4 daim ntawv;

2. Cov ntawv sib xyaw nrog tag nrho cov tuab ntawm 1.0, 1.2 thiab 1.4 tsis muab tag nrho cov ntawv, tab sis tuaj yeem muab kinfe nplej txiav lossis 1/2 daim ntawv.

Cov khoom uas muaj tag nrho cov thickness ntawm 5.0 thiab 8.0 yog customized khoom.

Lwm qhov ntau thiab tsawg thiab cov qauv tuaj yeem ua raws li cov neeg siv khoom thov

PCD

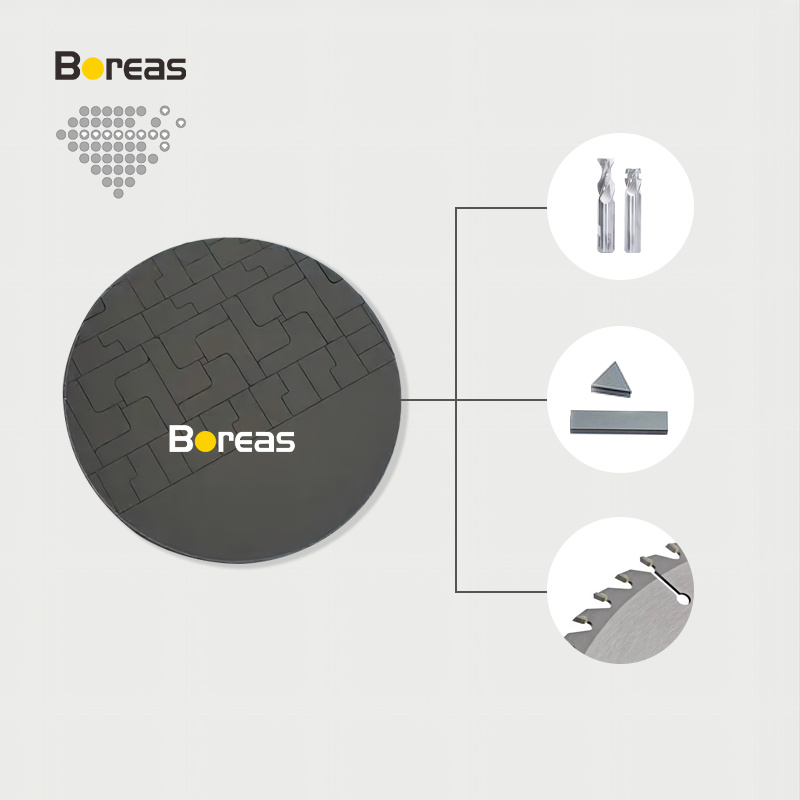

PCD txiav cov cuab yeej blanks

- PCD tej cuab yeej blanks raug kho kom tau raws li peb cov neeg siv khoom tshwj xeeb lossis cov kev xav tau.PCD tej cuab yeej blanks yog tsuas yog siv rau kev txiav thiab machining non-ferrous hlau thiab alloys xws li SI/Al alloys, txhuas, tooj liab thiab zoo sib xws alloys.Lawv kuj tau siv los ua cov khoom siv tsis yog xim hlau xws li ntoo, graphite, ceramics, yas, roj hmab thiab lwm yam, uas yuav tsum muaj kev tiv thaiv siab thiab lub neej ntev.

PCD txiav cov cuab yeej blanks

Ldeal rau pob zeb diamond pom hniav, kev tsim kho coring thiab drilling, pob zeb diamond cutters rau ntug-trimming, PCD inserts rau tig thiab milling, pob zeb diamond laum khoom rau lub qhov-drilling nyob rau hauv cov ntaub ntawv sib xyaw thiab Circuit Court boards, thiab lwm yam.

![[BRM-A] / Blocky Series Micron Pob Zeb Diamond Hmoov](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)

![[BRM-B] Ntses Series Micron Pob Zeb Diamond Hmoov](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660262dc476d894528.jpg)

![[BRM-GC] High Purity Micron Pob Zeb Diamond Hmoov](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026428c5ac995731.jpg)

![[BRM-GQ] Lub Zog Muaj Zog Micron Pob Zeb Diamond Hmoov](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602679f5e56a38683.jpg)

![[BRM-WSD] Micron Pob Zeb Diamond Hmoov rau Pob Zeb Diamond Hlau](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)

![[BRM-PCD] Micron Pob Zeb Diamond Hmoov rau PCD Synthesis](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660268f2aa17963361.jpg)

![[BRM-Z] Reshaped Mesh Pob Zeb Diamond Hmoov](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)

![[BRM-P] Crushed Mesh Pob Zeb Diamond Hmoov](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)

![[BRM-E] Ntsuab Crushed Mesh Pob Zeb Diamond](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66023652c98c857529.jpg)