Fihirisar Tauri (TI)

Ƙarfin ƙarfi na foda lu'u-lu'u abrasive yana da mahimmanci ga kayan aiki a cikin aikace-aikace. Yana rinjayar ingancin aiki da rayuwar sabis kai tsaye. Kamfanin Boreas yana dagewa cikin daidaiton inganci ta hanyar gwaji mai ƙarfi, don kiyaye taurin kowane tsari a cikin kunkuntar kewayo.

●Hanyar gwaji: Ɗaukar wasu samfurori don yin gwajin tasiri, sa'an nan kuma zazzage su, ƙididdige adadin wanda ya rage ainihin barbashi, shine ƙimar TI.

TTi (Fihirisar Tauri na Thermal):

TTI shine ma'aunin juriya na zafi don superabrasives. Tsawon yanayin zafi na grits lu'u-lu'u yana da mahimmanci musamman a cikin sarrafawa tun lokacin da yake tasiri kai tsaye akan ingancin sarrafawa, rayuwar kayan aiki, ingancin samarwa da farashi.

●Hanyar gwaji: Saka samfuran a cikin tanderun zafin jiki mai zafi ta hanyar dumama a cikin 1100 ℃ na mintuna 10, sannan bari samfuran suyi gwajin TI, ƙimar kashi shine ƙimar TTI.

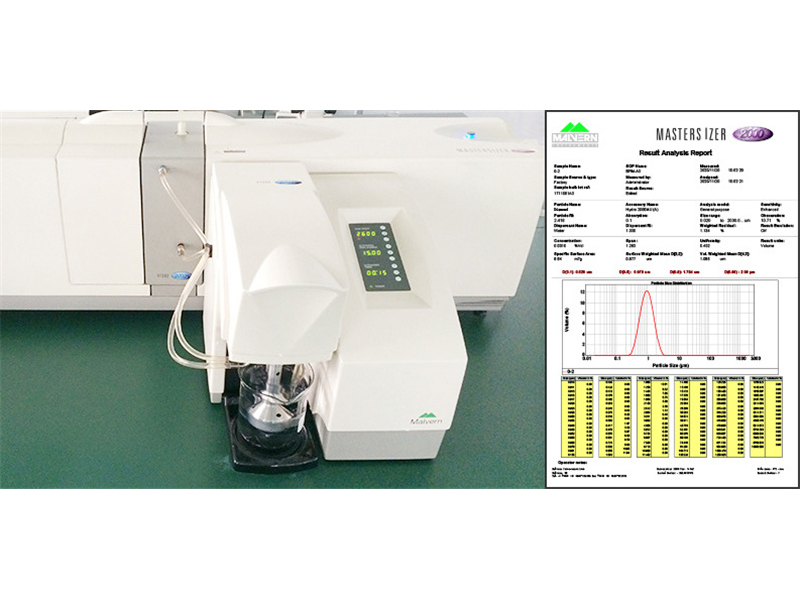

Gwajin Rarraba Girman Barbashi (PSD).

A matsayin babban madaidaicin abu, lu'u lu'u lu'u-lu'u micro foda zai sami mafi kyawun aiki a saman kammala ingancin aikin yanki idan ana iya kiyaye girman rarraba a cikin kewayon kunkuntar. Ka'idar gwaji shine abin da ya faru na tarwatsawa, ana iya ƙididdige rarraba kwayoyin halitta ta hanyar hasken da aka watsar zuwa ƙananan foda.

Hanyar gwaji: Saka samfurori a cikin injin gwaji, software na bincike zai nuna girman sakamakon rarraba.

Gwajin Magnetism

Magnetism na roba lu'u-lu'u foda an ƙaddara ta da ƙazanta na ciki. Ƙananan ƙazanta yana da, ƙananan magnetism, mafi girma da tauri, mafi kyawun siffar barbashi da kwanciyar hankali na thermal.

Hanyar gwaji: Saka abrasives a cikin kwandon gwaji, allon injin gwajin zai nuna ƙimar maganadisu.

Analyzer Siffar Barbashi

Wannan mai nazari na iya ba da cikakkun bayanai game da sifar kowane nau'in ɓangarorin, gami da sigogi kamar rabon al'amari, zagaye, da angular.

Hanyar gwaji: Sanya samfuran a ƙarƙashin na'urar hangen nesa don nazarin girman barbashi da siffa ta kyamarar dijital da fasahar sarrafa hoto na dijital.

SEM (Scanning Electron Microscope)

Ana amfani da microscopes na SEM don bincika foda lu'u-lu'u sosai. Suna taimakawa wajen ƙayyade girman, siffa, da sifofi na ɓangarorin, suna tabbatar da sun cika ka'idodin inganci don amfani daban-daban.

Rarraba Siffar Diamond

Yin amfani da na'urar rarrabuwar siffa, Boreas yana rarrabuwar barbashi na lu'u-lu'u zuwa nau'ikan kamar cubic, octahedral, da sifofin da ba na ka'ida ba, yana tabbatar da sifofi iri ɗaya waɗanda ke haɓaka ingancin samfur, inganci, da rayuwar kayan aiki a aikace-aikacen masana'antu.

Sieves Gwajin Electroformed

Ana amfani da sieves ɗin gwaji na lantarki don rarrabewa da rarraba barbashi na lu'u-lu'u da girmansu. Wadannan sieves an yi tare da daidai budewa, tabbatar da m barbashi size bincike ga ingancin iko a lu'u-lu'u foda samar.

Ana amfani da gwajin girman ta hanyar sieves na lantarki. Boreas kamfanin yana da m sha'anin matsayin don tabbatar da daidaito na barbashi size rarraba ta iko da shi a cikin kunkuntar kewayo.